Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

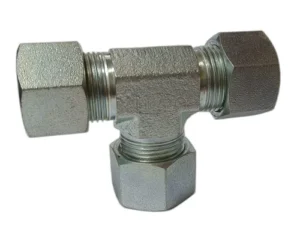

Hydraulic Equal Tee

A hydraulic equal tee is a hydraulic fitting that has been designed in such a way to combine three hydraulic components or pipes (commonly tubes or hoses) at an angle of 90 Degrees from one another. It’s known as an equal tee because, all three outlets of the tee are the same size. Hydraulic equal tees are available in various sizes and designs to suit varied hydraulic applications.

Types of Hydraulic Equal Tee

Hydraulic equal tees are available in different variants depending on the size and configuration like hydraulic equal elbow. The hydraulic equal tee plays an important part in the hydraulic systems, and some widely used types are:

We offer these tee in standard and customized specifications for the varied requirements of the customers. Threaded equal tees are used as the branch has a female thread connection for direct branch connection. They are a tee-shaped fitting with three threaded “arms”.

Welding equal tees are commonly used where the hydraulic system demands for a permanent connection of three pipes or equipment. You will receive 1 tee, It is made from a single piece of metal There are three openings in the fitting for connecting pipes Together.

Flanged equal tees are suitable where flanged connection to a hydraulic system is required. They are formed as a tee-fitting with three flanged branches for connection to the hydraulic system.

Socket weld equal tee is applied in pipe systems that are socket weld of hydraulic system. They are tee shape with three outlet socket weld seats.

Request a Quote to place order or make query

Materials Used For Hydraulic Equal Tee

Hydraulic equal tee are made with various kind of materials, according to its working conditions and use requirements. Some of the known materials include:

- Steel: Steel is the normal material for hydraulic equal tees. It is powerful, hard and resistant to high pressure and temperature. Steel connectors can be used in a variety of hydraulic applications such as agricultural, construction equipment and mobile machinery.

- Stainless Steel: It is used for applications where the hydraulic system needs to be corossion and temperature tolerant. They are ideal in food processing, chemical and pharmaceutical industries.

- Brass: Brass hydraulic fittings are ideal for applications that demand chemical resistance and low pressure. PNEUMATIC AND HYDRAULIC USE Brass fittings.

- Aluminum: Aluminum fittings are used on constructions where the hydraulic system must remain as light as possible. Aluminum fittings are common in aeronautical and automotive applications.

- Plastics: Plastics are used in the hydraulic system when required corrosion resistance, lower pressure and light fittings. Plastic connection pieces are used in chemical and food industries.

Installation of Hydraulic Equal Tee

Hydraulic equal tee installation is vital to right working order and avoiding leaks. The procedure for installation of hydraulic equal tees is as follows:

- Clean the joints: The fittings MUST be cleaned and free of debris prior to insertion. There is no room for dirt or contamination and anything can lead to a liquid loss and the subsequent hydraulic failures.

- Thread sealant application: Apply threaded sealant to the male threads of the hydraulic equal tee. The thread sealant blocks leaks and improves the assembly’s sealing performance between a fitting and a hydraulic system.

- Tighten the fittings: Hand-tighten the fittings, and use a wrench to tighten them to the manufacturer’s torque specification. If the fit tings are over- or under-tighted, leaks will occur and damage to the hydraulic system.

- Test the system: Following installation, check for leaks and functionality of the hydraulic system. If there is a leak, it should be repaired right away or else the hydraulic system could get damaged.

The hydraulic equal tee is integral for any hydraulic machines. They bearing the connection of three hydraulic parts and/or lines at a right angle to each other.