Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

What Is a Telescoping Pneumatic Cylinder Used For?

Introduction

As industries grow more compact and efficient, the need for smart motion systems increases. A telescoping pneumatic cylinder offers a space-saving solution that delivers long-stroke performance from a small, retracted size. These cylinders are commonly used in systems where a standard cylinder would take up too much space. Whether in automation, agriculture, or material handling, they make precise linear motion possible in tight spaces. In this post, we’ll explore what telescopic cylinders are and where they’re used across various industries.

Quick Overview of Telescoping Pneumatic Cylinders

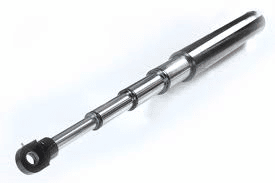

A telescoping pneumatic cylinder is a type of actuator that uses compressed air to extend and retract in stages. Much like how a telescope extends one section at a time, these cylinders are designed with nested sleeves—or “stages”—that extend sequentially when air is applied.

The beauty of this design is in its compactness. While retracted, the cylinder is short and easy to mount, but when extended, it can reach much longer distances than a standard single-stage cylinder of the same size.

There are generally two main types:

Single-acting telescopic pneumatic cylinder: Uses air to extend and relies on gravity or an external force to retract.

Double-acting telescopic pneumatic cylinder: Uses air for both extension and retraction, giving greater control and speed.

Each stage moves one after the other, with the smallest stage usually extending first and the largest last. This staged movement allows for a longer total stroke while keeping the body of the cylinder compact.

These cylinders are typically made from lightweight materials like aluminum or steel, ensuring durability without adding bulk. Because they use compressed air rather than hydraulic fluid, they’re cleaner and ideal for environments where leaks are not acceptable.

In short, the telescopic air cylinder provides an efficient and lightweight solution for long-stroke applications in limited spaces.

Key Applications Across Industries

Telescoping pneumatic cylinders have a wide range of applications due to their compact design and powerful reach. Their ability to operate efficiently in tight environments makes them a go-to choice across industries.

1. Industrial Automation

In fast-paced assembly lines, space is always a premium. Telescopic cylinders help perform tasks like pushing, lifting, or positioning parts without needing extra room. Their precise stroke control also makes them ideal for robotic arms and pick-and-place systems.

2. Material Handling

These cylinders are perfect for conveyor systems, loading docks, and sorting mechanisms. Their long reach and compact build mean they can extend to move products, then retract without obstructing the workflow.

3. Agriculture Equipment

In agricultural machinery, telescopic pneumatic cylinders are used in automated irrigation arms, adjustable harvest tools, and compact equipment attachments. Their light weight and low maintenance make them ideal for the rugged and remote conditions of the field.

4. Vehicle and Mobile Equipment

From truck tailgates to mobile ramps, telescopic cylinders provide the movement needed without adding much to the size or weight of the vehicle. They’re commonly used in compact lift systems where space constraints are critical.

5. Packaging and Processing Machinery

In vertical form-fill-seal machines or equipment that needs vertical motion, a telescopic air cylinder helps reduce the height profile of the system while still delivering the full stroke needed for the task.

These industries benefit from the reliability, compact size, and fast actuation of telescopic cylinders. Their adaptability and performance in limited-space scenarios make them an invaluable component in modern mechanical design.

Why Choose Telescopic Air Cylinders

There are several reasons engineers and system designers opt for a telescopic air cylinder instead of a standard pneumatic or hydraulic actuator.

1. Space-Saving Design

The most obvious benefit is compactness. These cylinders deliver a long stroke length from a body that’s much shorter when fully retracted. This makes them ideal for systems where space is at a premium.

2. Lightweight Construction

Made from aluminum or thin-walled steel, telescoping pneumatic cylinders are light and easy to install, especially in mobile or weight-sensitive systems.

3. Energy Efficiency

Because they use compressed air, these cylinders consume less power compared to hydraulic systems. They also generate less heat and require no fluid handling or pumps.

4. Clean Operation

No hydraulic oil means a cleaner working environment. This is crucial for industries like food processing, pharmaceuticals, and packaging, where contamination is not an option.

5. Versatility in Mounting

These cylinders can be mounted horizontally or vertically, giving designers more flexibility. Whether you need to lift something or push it forward, a telescoping pneumatic cylinder can be adapted to your application.

6. Cost-Effective Maintenance

Air systems generally require less maintenance than hydraulic ones. Plus, if a stage gets damaged, many telescopic models allow partial repair or stage replacement.

Overall, these cylinders provide a reliable, flexible, and clean way to achieve long linear motion—without the space and mess of other systems.

Final Thoughts

A telescoping pneumatic cylinder is a smart, compact solution for achieving long-stroke motion in tight environments. From automated assembly lines to agricultural machines and vehicle lifts, its benefits are seen across various industries.

Choosing a telescopic air cylinder means choosing efficiency, reliability, and adaptability. Whether you’re working in a small factory space or building a mobile machine, this type of cylinder can offer the reach you need—without sacrificing design constraints.

Looking to integrate one into your system? Consult with your pneumatic supplier to select the right model and configuration for your needs.