Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

TORQUE Hydraulic Valves

Torque brand hydraulic valves are a product line of hydraulic valves manufactured by Torque Industries. These valves are designed to control the flow of hydraulic fluid in various hydraulic systems, offering precise control and reliability. They might include directional control valves, pressure control valves, flow control valves, or other types, depending on the specific needs of the hydraulic system they are intended for. Torque brand hydraulic valves are typically used in industries such as manufacturing, construction, agriculture, and transportation, where hydraulic systems are commonly employed for power transmission and control

Torque brand directional control valves are components used in hydraulic systems to control the direction of fluid flow. These valves are crucial for directing hydraulic fluid to various actuators, such as cylinders or hydraulic motors, to control the movement of machinery or equipment.

Some features you might find in Torque brand directional control valves could include:

Solenoid Actuation: Many modern directional control valves are actuated by solenoids, providing precise electronic control over the valve’s position and thus the flow direction.

Manual Overrides: Manual overrides allow operators to manually actuate the valve in case of power failure or for maintenance purposes.

Modular Design: Modular valves allow for flexible configuration and adaptation to different hydraulic system requirements.

Multiple Spool Configurations: Directional control valves often come with multiple spools, allowing for different flow paths and configurations to suit specific applications.

Pressure Ratings: Valves may be designed to handle different pressure ratings depending on the demands of the hydraulic system they are used in.

Flow Rates: Valves may also be rated for specific flow rates to ensure proper operation within the hydraulic system.

Sealing and Durability: High-quality seals and materials are used to ensure durability and prevent leakage, even under high-pressure conditions.

Torque brand directional control valves, like those from other manufacturers, come in various sizes, configurations, and designs to meet the diverse needs of hydraulic systems in different industries and applications.

Manual Direction Control Valve

Solenoid Direction Control Valve

Piloted Operated Solenoid Directional Control Valve

Inline Check Valve

Flow Control Valves

Torque brand flow control valves are essential components in hydraulic systems that regulate the flow rate of hydraulic fluid to specific parts of the system. These valves allow for precise control over the speed of actuators, such as cylinders or motors, ensuring smooth and efficient operation of machinery and equipment.

Here are some features commonly found in Torque brand flow control valves:

Adjustable Flow Rate: These valves typically feature an adjustable mechanism to regulate the flow of hydraulic fluid, allowing operators to control the speed of hydraulic actuators.

Bi-Directional Flow Control: Some flow control valves are designed to regulate flow in both directions, providing flexibility in hydraulic system design.

Pressure Compensated: Certain valves may be pressure-compensated, meaning they adjust the flow rate based on changes in system pressure to maintain consistent performance.

Modular Design: Similar to directional control valves, flow control valves may have a modular design, allowing for easy integration into various hydraulic systems and configurations.

Various Configurations: Flow control valves may come in different configurations, such as in-line, cartridge, or manifold-mounted, to suit different installation requirements.

Materials and Seals: High-quality materials and seals are used to ensure durability and reliable performance, even in demanding operating conditions.

Compatibility: Torque brand flow control valves are designed to be compatible with a wide range of hydraulic fluids and systems, offering versatility and compatibility with different equipment and applications.

These features make Torque brand flow control valves crucial components in hydraulic systems across industries such as manufacturing, construction, agriculture, and more, where precise control over hydraulic fluid flow is essential for efficient operation.

Pilot Check Valve

2 Way Flow Control Valve

Throttle Check Valve

Pressure Compensated Flow Control Valve

Modular Valves

Torque brand modular valves are versatile hydraulic components designed to offer flexibility and adaptability in various hydraulic system configurations. These valves typically consist of individual modules that can be combined or stacked together to create custom valve assemblies tailored to specific application requirements.

Here are some key features and aspects of Torque brand modular valves:

Modularity: The modular design allows for easy customization and expansion of hydraulic systems by combining different modules to create valve assemblies suitable for specific functions and tasks.

Interchangeability: Modules from the Torque brand modular valve lineup are often designed to be interchangeable, enabling users to swap out modules as needed without requiring significant changes to the overall system.

Versatility: These valves can perform a wide range of functions, including directional control, flow control, pressure control, and more, depending on the modules used and how they are configured.

Compact Design: Despite their versatility, Torque brand modular valves are typically designed to be compact, making them suitable for installations where space is limited.

Ease of Maintenance: The modular design also facilitates maintenance and servicing, as individual modules can be easily accessed and replaced if necessary, minimizing downtime and reducing maintenance costs.

Integration: Torque brand modular valves are engineered to integrate seamlessly with other hydraulic components and systems, ensuring compatibility and optimal performance.

Quality and Reliability: Like other products from Torque Industries, modular valves are manufactured to high-quality standards, using durable materials and precision engineering to ensure reliable operation even in demanding environments.

These features make Torque brand modular valves popular choices for a wide range of applications across industries such as manufacturing, agriculture, construction, and more, where customizable and adaptable hydraulic solutions are needed to meet specific requirements.

Modular Reducing Valve

Modular Relief Valve

Modular Throttle Check Valve

Modular Pilot Check Valve

Pressure Control Valves

Torque brand pressure control valves are critical components in hydraulic systems that regulate and control the pressure of hydraulic fluid within the system. These valves help maintain safe operating pressures, protect hydraulic components from damage due to excessive pressure, and ensure consistent performance of machinery and equipment.

Here are some features commonly found in Torque brand pressure control valves:

Pressure Relief: Pressure relief valves are designed to limit the maximum pressure in a hydraulic system by diverting excess fluid flow back to the reservoir when the pressure exceeds a preset level.

Pressure Reducing: Pressure reducing valves regulate the pressure of hydraulic fluid downstream of the valve to maintain it at a set, lower pressure level.

Pressure Sequence: Pressure sequence valves ensure that one hydraulic function operates only after a predetermined pressure level is reached in another part of the system, allowing for sequential operation of hydraulic actuators.

Pressure Sensing: These valves often incorporate pressure sensing mechanisms to monitor system pressure and adjust valve operation accordingly.

Adjustability: Many Torque brand pressure control valves feature adjustable pressure settings, allowing operators to fine-tune the pressure levels based on the requirements of the hydraulic system and the application.

Modular Design: Similar to other types of hydraulic valves, pressure control valves may have a modular design, enabling easy integration into various hydraulic systems and configurations.

Materials and Seals: High-quality materials and seals are used in the construction of Torque brand pressure control valves to ensure durability and reliable performance even in harsh operating conditions.

Compatibility: These valves are designed to be compatible with a wide range of hydraulic fluids and systems, offering versatility and compatibility with different equipment and applications.

Torque brand pressure control valves play a crucial role in maintaining the performance, safety, and efficiency of hydraulic systems across industries such as manufacturing, construction, agriculture, and more. Their precision engineering and reliable operation make them trusted components in demanding hydraulic applications.

Solenoid operated relief valve

Pilot Operated Relief Valve

Solenoid Control Relief Valve

Unloading Relief Valve

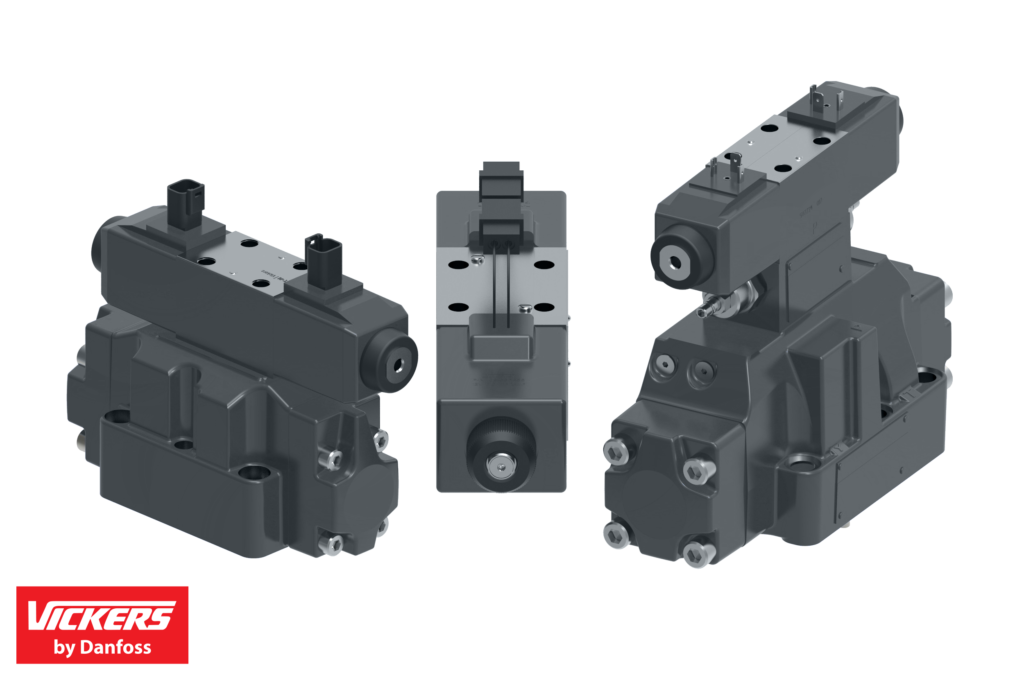

Proportional Valves

Torque brand proportional valves are advanced hydraulic components that provide precise control over the flow rate, direction, or pressure of hydraulic fluid in proportion to an electrical or mechanical input signal. These valves are commonly used in applications where precise and variable control of hydraulic systems is required, such as in industrial machinery, automation systems, and aerospace equipment.

Here are some key features of Torque brand proportional valves:

Proportional Control: These valves offer proportional control, meaning that the output (flow rate, direction, or pressure) is directly proportional to the input signal. This allows for precise control over the hydraulic system’s operation.

Electro-Hydraulic Actuation: Proportional valves from Torque typically utilize electro-hydraulic actuation, where an electrical signal controls the hydraulic valve’s operation through a combination of electrical and hydraulic components.

Linear Response: Torque brand proportional valves are engineered to provide a linear response to input signals, ensuring consistent and predictable control over the hydraulic system.

Adjustability: Many proportional valves offer adjustable parameters, such as gain, offset, and response time, allowing operators to fine-tune the valve’s performance to suit specific application requirements.

Integration: These valves are designed to integrate seamlessly with electronic control systems, PLCs (Programmable Logic Controllers), and other automation equipment commonly found in modern hydraulic systems.

Feedback Mechanisms: Some proportional valves incorporate feedback mechanisms, such as position sensors or pressure transducers, to provide closed-loop control and enhance precision and accuracy.

Compact Design: Despite their advanced capabilities, Torque brand proportional valves are typically designed to be compact and lightweight, making them suitable for installation in space-constrained environments.

Durability and Reliability: High-quality materials and precise engineering ensure that Torque brand proportional valves are durable and reliable, capable of withstanding harsh operating conditions and delivering consistent performance over time.

These features make Torque brand proportional valves essential components in applications where precise control and variability of hydraulic systems are critical, offering enhanced performance, efficiency, and safety.

Proportional Electrohydraulic Relief Valve

Proportional Electrohydraulic Pilot Relief Valve

Proportional Electrohydraulic Relief & Flow Control Valve

Over Central Valve