Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

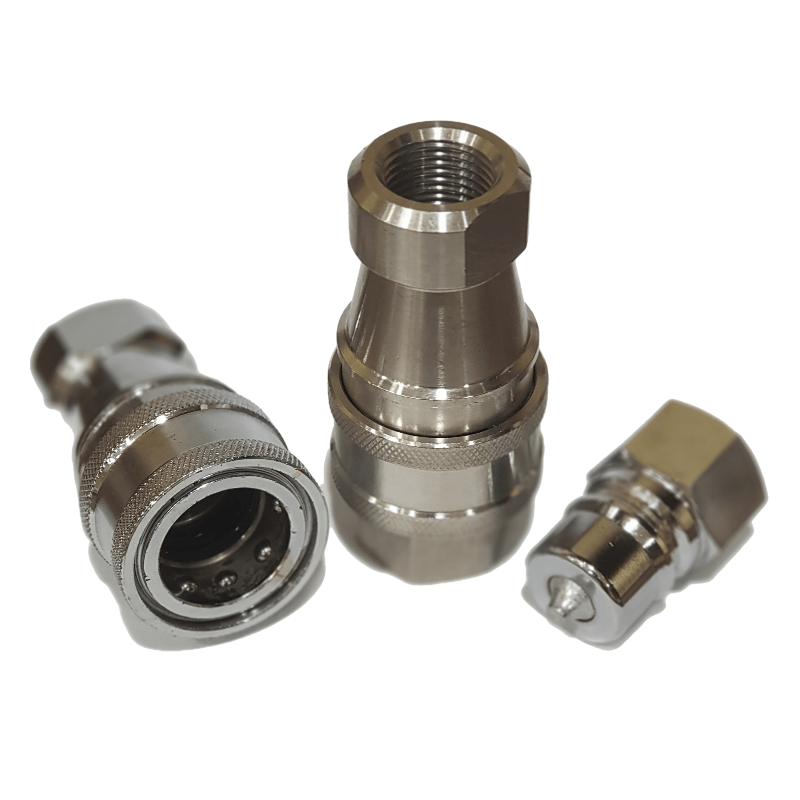

Quick Release Couplings – Double Check Valve

Quick release couplings Double Check Valve, often referred to as a double check valve quick disconnect or coupling, is a specialized type of quick release coupling designed with two check valves to prevent the backflow of fluids when disconnected. These couplings are commonly used in applications where preventing contamination and spillage is crucial

Key Features of Quick Release Coupling Double Check Valve

- Two Check Valves:

- The double check valve design incorporates two check valves on both the male and female ends of the coupling. These valves prevent the flow of fluid in both directions when the coupling is disconnected.

- Prevention of Contamination:

- The primary function of double check valve quick release couplings is to prevent the contamination of fluids. By incorporating two check valves, they provide an extra layer of protection against backflow, ensuring that the system remains sealed and clean.

- Leak Prevention:

- These couplings help prevent leaks in the system by sealing off both ends when disconnected. This is especially important in applications where fluids are hazardous or need to be contained within a closed system.

- Quick and Easy Connection:

- Similar to standard quick release couplings, double check valve couplings are designed for quick and easy connection and disconnection. This feature enhances the efficiency of fluid transfer processes.

- Diverse Applications:

- Double check valve quick release couplings find applications in various industries, including hydraulic, pneumatic, and fluid handling systems, where preventing contamination during disconnection is critical.

Design and Construction of Quick Release Couplings Double Check Valve

- Double Check Valve Configuration:

- The key feature of these couplings is the incorporation of two check valves – one on the male end and one on the female end. These check valves act as barriers to prevent backflow when the coupling is disconnected.

- Material Selection:

- Double check valve quick release couplings are typically constructed from materials compatible with the fluids they will handle. Common materials include stainless steel, brass, and high-quality engineering plastics. The selection depends on factors such as chemical compatibility, pressure requirements, and environmental conditions.

- Seals and O-rings:

- Seals and O-rings are critical components to ensure a reliable and leak-free connection. High-quality elastomers, often made of materials like Viton or Nitrile, are used for these seals to provide resilience and chemical resistance.

- Connection Mechanism:

- The connection mechanism allows for quick and easy coupling and uncoupling. Depending on the design, these couplings may feature a push-to-connect mechanism, a threaded connection, or other user-friendly mechanisms.

- Spring-Loaded Check Valves:

- The check valves are typically spring-loaded to ensure a positive and prompt closure when the coupling is disconnected. This helps prevent fluid backflow and minimizes the risk of contamination.

- Valve Design:

- The check valves are designed to open when the couplings are connected, allowing the fluid to flow in the desired direction. When disconnected, the check valves close automatically, preventing fluid from flowing in either direction.

Salient Features of Double Check Valve Quick Release Couplings

- Prevention of Contamination:

- The primary purpose of double check valve quick release couplings is to prevent the backflow of fluids, ensuring that contaminants do not enter the system during disconnection.

- Leak Prevention:

- By sealing off both ends when disconnected, these couplings help prevent leaks in the system, maintaining the integrity of the fluid transfer process.

- Quick Connection and Disconnection:

- Similar to standard quick release couplings, these couplings allow for rapid and efficient connection and disconnection, reducing downtime and improving operational efficiency.

- Versatility:

- Double check valve quick release couplings are versatile and find applications in various industries, including hydraulic, pneumatic, chemical processing, and more.

- User-Friendly Design:

- The design often includes features that make the coupling user-friendly, such as ergonomic handles or grips, color-coding for easy identification, and intuitive connection mechanisms.

- Durability:

- Constructed from durable materials, these couplings are designed to withstand the rigors of industrial environments, including pressure variations, temperature changes, and exposure to different fluids.

- Compatibility:

- These couplings are designed to be compatible with a wide range of fluids, making them suitable for diverse applications.

Advantages of Double Check Valve Quick Release Couplings

- Enhanced Safety:

- The double check valve design provides an extra layer of safety by preventing backflow, especially in applications where fluid contamination could have serious consequences.

- Reduced Contamination Risk:

- The use of double check valves significantly reduces the risk of fluid contamination, making these couplings suitable for applications where maintaining fluid purity is critical.

- Efficiency in Fluid Transfer:

- The quick and easy connection and disconnection of these couplings contribute to the efficiency of fluid transfer processes, particularly in applications with frequent changes or maintenance requirements.

- Flexibility:

- The versatility of double check valve quick release couplings allows them to be used in a wide range of industries and applications, providing flexibility and adaptability.

- Environmentally Friendly:

- By preventing leaks and spills, these couplings contribute to environmental protection and safety, particularly in applications where the fluids being transferred are hazardous.

- Ease of Use:

- The user-friendly design of these couplings, with features like color-coded handles or intuitive connection mechanisms, makes them easy to use, reducing the likelihood of user errors.

- Extended Equipment Lifespan:

By preventing contamination and reducing the risk of leaks, these couplings contribute to the overall reliability and longevity of hydraulic or pneumatic systems and equipment

Double check valve quick release couplings offer an effective solution for preventing fluid contamination and enhancing safety in various industrial applications. Their design, construction, and features make them valuable components in systems where maintaining the integrity of fluid transfer processes is paramount