Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

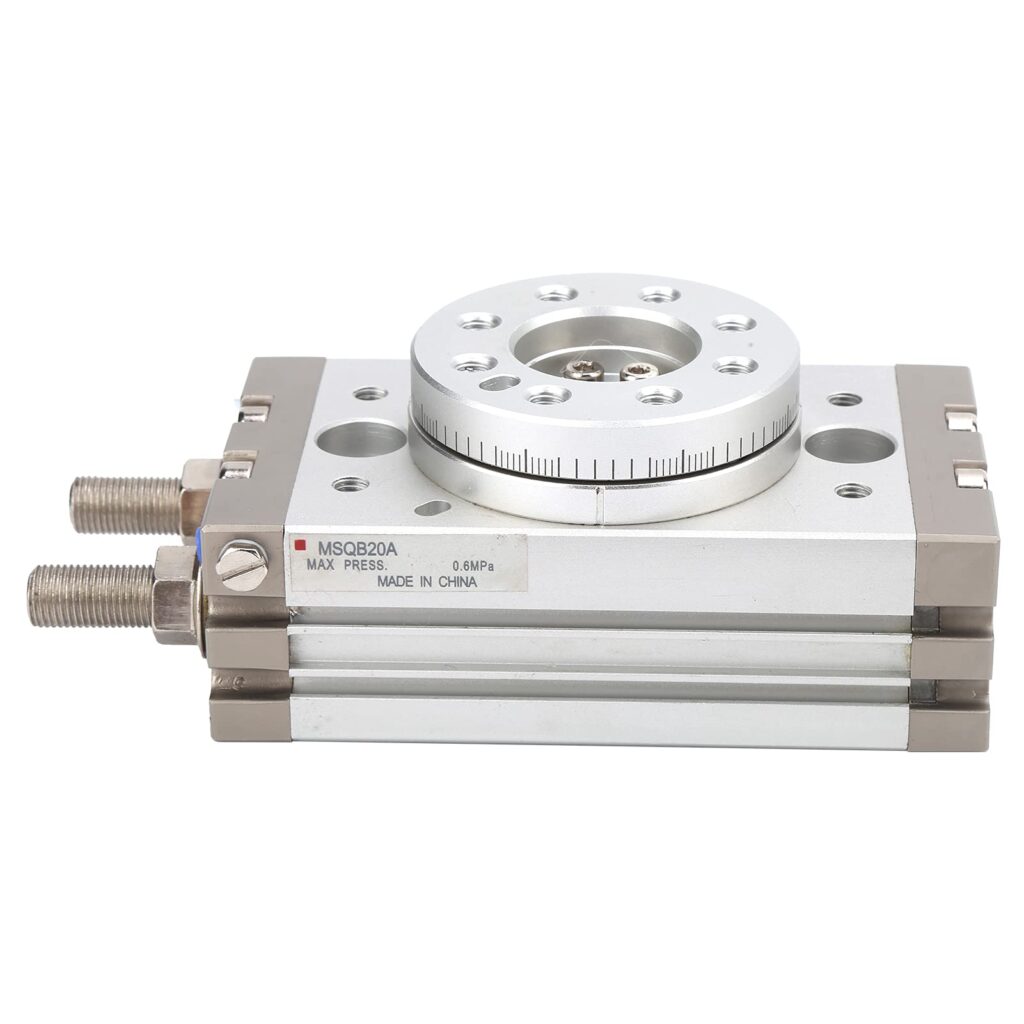

A pneumatic rotary cylinder is a type of pneumatic actuator designed to convert compressed air energy into rotary motion. Unlike linear cylinders that produce linear motion, rotary cylinders create rotational movement. These devices are used in various industrial applications where controlled rotary motion is required

Features of Pneumatic Rotary Cylinder

- Rotary Motion:

- Pneumatic rotary cylinders convert pneumatic pressure into continuous rotary motion.

- Compact Design:

- Rotary cylinders are often compact, making them suitable for applications with limited space.

- Various Operating Angles:

- They can operate through various angles, such as 90 degrees, 180 degrees, or even continuous rotation, depending on the specific design.

- Adjustable Rotation Speed:

- The speed of rotation can often be controlled by adjusting the air pressure or using flow control valves.

- Bidirectional Operation:

- Depending on the design, pneumatic rotary cylinders can rotate in both clockwise and counterclockwise directions.

- Different Mounting Options:

- Rotary cylinders come with various mounting options, allowing for flexibility in installation and integration into different systems.

Working Principle of Pneumatic Rotary Cylinder

- Piston and Rack-Pinion Mechanism:

- Some rotary cylinders use a piston and rack-pinion mechanism. Compressed air is supplied to move the piston, which, in turn, engages a rack-pinion mechanism to create rotary motion.

- Vane Mechanism:

- Another common design involves a vane mechanism, where compressed air acts on vanes or blades to produce rotary motion.

- Helical Gear Mechanism:

- In certain rotary cylinders, a helical gear mechanism is employed to convert linear motion into rotary motion.

- Rack-and-Pinion Mechanism:

- A rack-and-pinion system may be used, where linear motion of the piston is converted into rotary motion through the engagement of a rack and pinion.

Applications of Pneumatic Rotary Cylinder

- Indexing Tables:

- Pneumatic rotary cylinders are commonly used in indexing tables where precise angular positioning is required for manufacturing processes.

- Conveyors:

- In material handling systems, rotary cylinders can be used to control the orientation of conveyed items.

- Packaging Machinery:

- Rotary cylinders are employed in packaging equipment for tasks such as sealing, labeling, and capping.

- Assembly Lines:

- Rotary cylinders play a role in assembly lines, providing controlled rotation for tasks like product assembly or testing.

- Automated Machinery:

- Various automated machines use pneumatic rotary cylinders for tasks involving rotary motion, such as in robotic arms and grippers.

- Printing and Labeling:

- In printing and labeling machines, pneumatic rotary cylinders help control the positioning of print heads or labeling devices.

- Machine Tools:

- Rotary cylinders are used in machine tools for tasks requiring rotary motion, such as workpiece indexing or tool positioning.

Considerations and Maintenance of Pneumatic Rotary Cylinder

- Air Quality:

- Clean and dry compressed air is crucial for the longevity and efficient operation of pneumatic rotary cylinders.

- Lubrication:

- Proper lubrication of moving parts is essential to reduce friction and ensure smooth rotary motion.

- Seal Integrity:

- Regular inspection of seals is important to prevent air leaks and maintain the efficiency of the cylinder.

- Control Valve Maintenance:

- Maintenance of directional control valves and other control components is necessary for proper functioning.

- Mounting and Alignment:

- Proper mounting and alignment are crucial for ensuring that the rotary cylinder operates smoothly and accurately.

Pneumatic rotary cylinders provide a versatile solution for applications requiring controlled rotary motion. Their compact design, bidirectional operation, and adaptability to various mounting options make them suitable for a wide range of industrial processes. Regular maintenance and adherence to manufacturer guidelines are essential for ensuring the reliability and longevity of pneumatic rotary cylinders in their intended applications.