Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

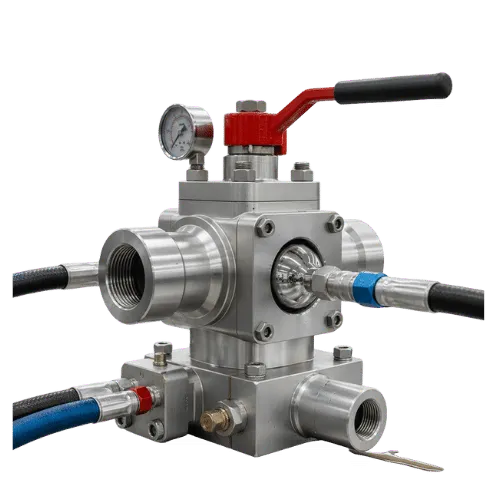

Hydraulic Ball Valve

High-Pressure Flow Isolation Solutions

Hydraulic ball valve are essential flow-isolation components in high-pressure hydraulic circuits. Engineered and prepared for rapid shutoff, zero leakage performance and long lifecycle durability, these valves ensure operational continuity across challenging industrial environments. Hydrofit Engineers manufactures and supplies a extensive portfolio of precision machined hydraulic ball valves to meet stringent fluid-power system requirements.

What Is a Hydraulic Ball Valve?

These high pressure hydraulic ball valves are quarter-turn isolation valves designed to control or block the flow of hydraulic oil under high pressure. Their internal ball rotates 90 degrees within their respective bodies for instantaneous open/close action while maintaining minimal pressure drop.

These hydraulic valves can be found in hydraulic power packs, mobile machinery, industrial automation lines, heavy earthmoving equipment and high-pressure fluid handling systems.

Key Features & Technical Value Proposition

Hydrofit Engineers specializes in producing hydraulic ball valves made with strong materials and precise control parameters that meet exacting specifications, for reliable performance.

- High-pressure endurance meeting industry benchmarks

- Quarter-turn operational efficiency for fast isolation

- Minimum flow resistance can be achieved using full-bore or reduced-bore configurations, which allow for an effective solution.

- Leakproof sealing mechanisms supporting high cycle performance.

- Corrosion-resistant surface treatments for harsh environments

- Optimized torque characteristics provide seamless handle operation

Types of Hydraulic Ball Valves We Offer

Hydrofit Engineers provides an expansive portfolio to satisfy diverse system requirements:

- High-Pressure Hydraulic Ball Valve: Purpose-built for hydraulic lines requiring robust shutoff under heavy load conditions.

- Two-Way Hydraulic Ball Valve: Standard open/close configuration for linear hydraulic flow paths.

- Three-Way Hydraulic Ball Valves: Use for diverting, mixing or directional control within complex hydraulic circuits.

- Stainless Steel Hydraulic Ball Valves: These fluid systems are ideal for harsh environments, offshore applications and critical fluid systems requiring high-grade metallic integrity.

- Threaded/Flanged Ball Valves: Available with various end-connection standards to facilitate smooth system integration.

Application of hydraulic Ball valve

Ball valves have a variety of applications:

- Hydraulic power units for mobile machinery & construction equipment

- Press machines & hydraulic presses are essential tools in industrial process lines, offering both mechanical and hydraulic pressing capability for various tasks.

- Material Handling Systems in Steel plants, mining operations and offshore systems

- Reliable and precise isolation precision make them indispensable components in fluid-power ecosystems. Here is the ultimate guide about ball valve read more.

Why choose Hydrofit Engineers for Hydraulic High Pressure Ball Valves?

Hydrofit Engineers provides cost-effective hydraulic solutions with solid engineering knowledge and supply-chain flexibility, which result in greater value creation for clients. Some advantages offered by us:

- Precision engineered components from industry standard materials.

- Competitive India-wide delivery capabilities.

- Compliance with international fluid power specifications.

- Production batches receive consistent quality assurance across production batches.

- System Integration Support Services provided.

Looking for hydraulic high pressure ball valves?

We’re just a call away

FAQs

What pressure rating do hydraulic ball valves support?

The range is generally for medium to high pressure up to 5,000 PSI (depending on model and material).

Can stainless steel ball valves be used in corrosive applications?

Yes – SS ball valves are intended for offshore, chemical process and severe-service applications.

Can you automate hydraulic ball valves?

Yes. They are also available with pneumatic or electric actuators for automatic flow isolation.

What do 2-way and 3-way ball valves mean?

A 2-way ball valve opens or shuts a single flow path whereas the 3-way ball valve diverts or mixes flow among three ports.