Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

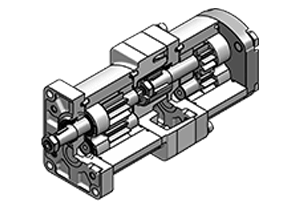

Hydraulic Tandem Pump

Hydrofit Engineers specialize in providing high-quality tandem gear pumps, offering efficient solutions for diverse hydraulic systems requiring multiple pressure and flow rates.

Tandem pumps are a key element in hydraulic systemss since they provide a one-of-a-kind solution for combining several gear pump sections into one productive and space-saving unit. This provides for outputting fluid at varying flow rates and pressure levels, so tandem pumps are perfect for a wide variety of industrial and mobile applications. Modern Hydraulic Systems – Design, Function and Applications of Tandem Pumps In the following two-part article we look at modern hydraulic systems, their design and how a tandem pump can be used to double output pressures or utilize multiple hydraulic functions in these increasingly common systems.

Table of Contents

What is a Tandem Pump?

A tandem pump, which is commonly known as a double gear pump, incorporates two or more sections of gear pumps in one housing. Each portion can work independent to reach the needs of fluids being delivered for different lines at different pressures / flows as per the working principle of tandem gear pump. The pump sections are usually all belt/base driven for synchronized operational with a mush common input shaft.

Tandem Pump Construction and Design

Gears: At the heart of the tandem-pump are gears, typically external gears that interlock and pump. They are usually constructed of strong materials, such as steel or cast iron, to minimize wear for extended gear life.

Housing: The pump housing covers the gears and keeps them close enough for the pump to work. It’s also meant to withstand the pressures created by the pump.

Shaft: The tandem-pump has a single input shaft that drives rear of the gears back of all sections, leading to uniform synchronization and operational performance.

In series: In series piping, the output of one pump section is discharged directly into the next, achieving higher pressure. Such an arrangement is useful for when there are different pressure levels desired at different sections of a hydraulic system.

Parallel Set-Up: In a parallel setup, each pump section has its own dedicated discharge which offers more than one flow rate on a single pump. This arrangement is useful for apparatus which must deliver liquid to multiple circuits that draw volumes of fluid at various different rates.

How Does a Tandem Pump Work?

The operating concept of a tandem-pump is based on that of a single section gear pump except for the presence of additional sections. Gears in the individual pump stages are driven, and thus rotated, by rotation of the input shaft.

The gears mesh to form a vacuum at the pump inlet that draws hydraulic fluid into the pump. The fluid is thereby confined between the gear teeth and the housing, being subsequently brought to the outlet side of the pump. The gears exert the force against the fluid, pushing it from the pump and into the hydraulic system. Discover more about working way of pumps here.

This is a “dual action” pump so each section can be run independently, this provides the benefit to fine tuning of multiple circuits. That is to say, one flow path can feed out a fluid at high speed for low pressure side and an other is feeding it with slow speed for high pressure side by use of the pumping apparatus.

Find the best price for the Tandem Gear Pump

Tandem gears are key to hydraulic applications where fluid at targeted pressures flow-rate is desired. Available in range of lengths and from a variety of construction materials, many fall on the more economical end of the cost spectrum to fit easily within any budget. Tandem pumps (2 pump sections in one unit) provide a coherent and competent answer to complex hydraulic systems for a variety of purposes at the same time.