Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Types of Hydraulic Gear Pumps

At Hydrofit Engineers, you will find the wide array of gear pumps covering OP Series, 1P Series, 2P Series, tandem gear pumps and triple gear Pumps. We are hydraulic gear pumps supplier in Chennai. We offer a DOWTY, BOSS, SUPREMO, WELEX and EXCEL Gear Pumps.

Hydraulic gear pumps are devices that are used to transfer fluids from one place to another through the use of gears. They are an essential component in hydraulic systems that are used in a variety of industries, such as construction, agriculture, mining, and transportation. In this article, we will discuss hydraulic gear pumps, their components, and how they work.

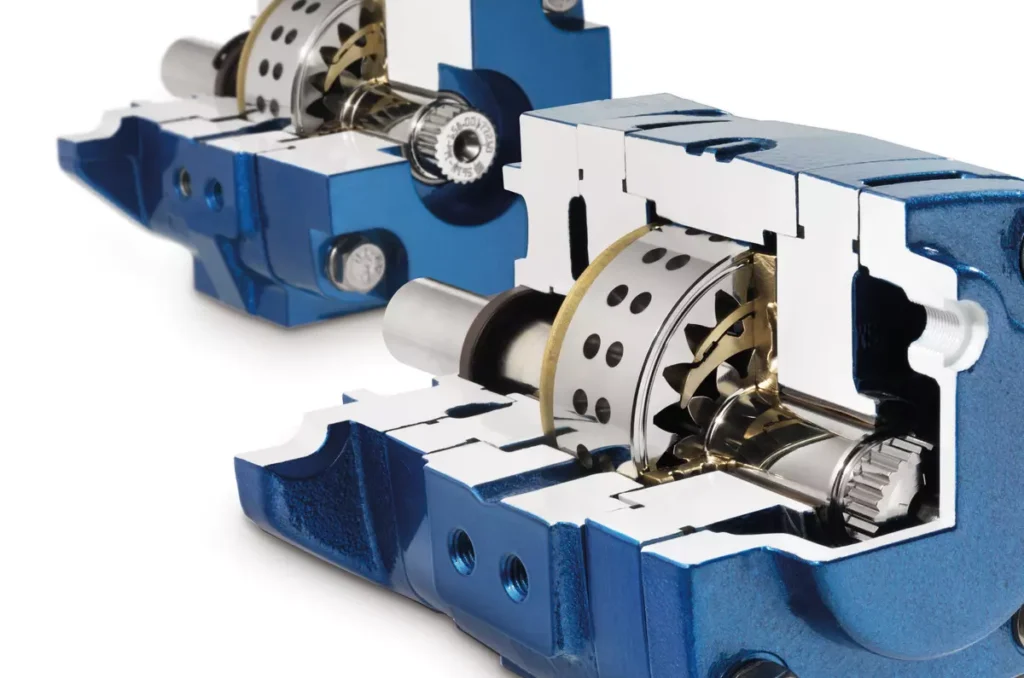

Components of a Hydraulic Gear Pumps

A hydraulic gear pump consists of a few main components, which are:

- Gear Set: This is the main component of a gear pump, and it is made up of two gears that mesh together. These gears are typically made of high-strength materials such as steel or bronze.

- Pump Housing: The pump housing is the outer casing of the pump that contains the gear set. It is usually made of aluminum or cast iron.

- Inlet and Outlet Ports: The inlet and outlet ports are the openings in the pump housing where fluid enters and exits the pump.

- Seals and Gaskets: Seals and gaskets are used to prevent fluid from leaking out of the pump. They are typically made of rubber or other flexible materials.

- Drive Shaft: The drive shaft is used to turn the gear set. It is typically connected to an electric motor or an engine.

Types of Hydraulic Gear Pumps

OP series gear pumps are typically constructed with high-precision gear sets that ensure efficient and reliable fluid transfer. The gears in these pumps are usually made from hardened steel or other high-strength materials, which can withstand high pressures and resist wear over time. The casing of OP series pumps is often made from durable materials like cast iron or aluminum, providing a robust structure that can endure harsh operating conditions.

The choice of materials in OP series gear pumps is critical for their performance and longevity. High-quality, hardened steel is used for the gears to minimize wear and tear and extend the pump’s life. The pump housing is often made from cast iron or aluminum, which provides a good balance between strength and weight. The seals and bearings used in OP series pumps are also of high quality, ensuring minimal leakage and efficient operation. We are the hydraulic gear pump supplier in chennai.

OP series gear pumps are designed with several operational features that set them apart from standard gear pumps:

- High Efficiency: The precision-engineered gears and robust construction minimize internal leakage and maximize volumetric efficiency.

- Pressure Capability: OP series pumps can operate at higher pressures compared to standard gear pumps, making them suitable for demanding applications.

- Compact Design: Despite their robust construction, OP series pumps are designed to be compact, allowing them to fit into tight spaces without compromising performance.

- Quiet Operation: The advanced design reduces noise and vibration, providing quieter operation compared to traditional gear pumps.

Some common applications include:

- Industrial Machinery: Used in hydraulic systems for manufacturing and processing equipment.

- Construction Equipment: Powers hydraulic systems in excavators, loaders, and other heavy machinery.

- Agriculture: Utilized in hydraulic systems for tractors, harvesters, and other farming equipment.

- Automotive: Employed in hydraulic systems for power steering, transmission, and braking systems.

- Marine: Powers hydraulic systems in boats and ships, including steering and winching systems.

The 1P Series gear pumps are designed with simplicity and efficiency in mind. These pumps consist of a pair of gears – one driving gear and one driven gear- enclosed within a pump housing. As the gears rotate, they create a vacuum at the pump inlet, drawing fluid in, and then pushing it out through the outlet.

- Gear Design: The gears in 1P Series pumps are typically straight-cut or spur gears, which are straightforward in design and efficient in operation.

- Pump Housing: The housing is usually made from durable materials like cast iron or aluminum, providing structural integrity and resistance to wear and tear.

- Seals and Bearings: High-quality seals and bearings ensure minimal leakage and smooth operation, contributing to the pump’s overall reliability.

The materials used in the construction of 1P Series gear pumps are selected for their durability and compatibility with various fluids. Common materials include:

- Gears: Hardened steel or sintered metal, providing excellent wear resistance.

- Housing: Cast iron for heavy-duty applications or aluminum for lighter, more compact designs.

- Seals and Bearings: High-grade elastomers and bearings designed to withstand the operating pressures and temperatures.

1P Series gear pumps are characterized by their straightforward operational features:

- Fixed Displacement: These pumps deliver a consistent volume of fluid per rotation, making them ideal for applications requiring a steady flow.

- Moderate Pressure Capability: Typically designed for low to medium pressure applications, these pumps are suitable for a wide range of industrial uses.

- Simplicity and Reliability: The simple design translates to fewer moving parts, reducing the likelihood of mechanical failure and making maintenance easier.

- Simple Design: The simplicity of the 1P Series gear pumps is one of their most significant advantages. The straightforward gear mechanism ensures reliable operation and ease of maintenance.

- Consistent Performance: With a fixed displacement design, 1P Series gear pumps provide a steady and predictable flow rate, which is crucial for many hydraulic applications.

- Durability: Constructed from high-quality materials, these pumps are designed to withstand the rigors of continuous operation in various environments.

- Cost-Effective: The uncomplicated design and construction make 1P Series gear pumps a cost-effective solution for many applications, offering a good balance between performance and price.

The 2P Series gear pumps are designed to deliver superior performance in demanding applications. These pumps feature precision-engineered components that ensure high efficiency and reliability.

- Gear Design: The gears in 2P Series pumps are typically helical or spur gears. Helical gears are often preferred for their smooth and quiet operation.

- Pump Housing: The housing is constructed from durable materials such as cast iron or aluminum, providing the necessary strength to withstand high-pressure environments.

- Seals and Bearings: High-quality seals and bearings are used to ensure minimal leakage and smooth operation, contributing to the pump’s overall durability and performance.

The materials used in 2P Series gear pumps are selected for their ability to withstand harsh operating conditions and provide long-term reliability.

- Gears: Made from hardened steel or other high-strength alloys, offering excellent wear resistance and durability.

- Housing: Cast iron for heavy-duty applications or aluminum for a lighter, more compact design.

- Seals and Bearings: High-grade elastomers and bearings that can handle the operating pressures and temperatures typical in hydraulic systems.

2P Series gear pumps are characterized by their robust operational features:

- Variable Displacement: These pumps can adjust flow rates to match system demands, enhancing efficiency and reducing energy consumption.

- High Pressure Capability: Designed to operate at medium to high pressures, making them suitable for demanding applications.

- Efficiency: Advanced gear designs and high-quality materials ensure high volumetric efficiency, minimizing internal leakage and maximizing performance.

- Quiet Operation: The use of helical gears and precision manufacturing techniques results in quieter operation compared to standard gear pumps.

Common applications include:

- Industrial Machinery: Used in hydraulic systems for manufacturing and processing equipment where consistent and high-pressure fluid flow is required.

- Construction Equipment: Powers hydraulic systems in heavy machinery such as excavators, loaders, and cranes, which operate under demanding conditions.

- Agriculture: Utilized in hydraulic systems for tractors, harvesters, and other farming equipment that require robust and reliable performance.

- Automotive: Employed in power steering systems, transmissions, and lubrication systems in vehicles.

- Marine: Used in hydraulic systems for steering, winching, and other onboard machinery, where reliability and efficiency are crucial.

The 3P Series hydraulic gear pumps are designed to deliver exceptional performance and reliability. These pumps feature precision-engineered components that ensure high efficiency and durability.

- Gear Design: The gears in 3P Series pumps are typically helical or spur gears. Helical gears are often preferred for their smooth and quiet operation, while spur gears offer simplicity and efficiency.

- Pump Housing: The housing is constructed from high-strength materials such as cast iron or aluminum, providing the necessary robustness to withstand high-pressure environments.

- Seals and Bearings: High-quality seals and bearings are used to ensure minimal leakage and smooth operation, contributing to the pump’s overall durability and performance.

The materials used in the construction of 3P Series hydraulic gear pumps are selected for their ability to withstand harsh operating conditions and provide long-term reliability.

- Gears: Made from hardened steel or other high-strength alloys, offering excellent wear resistance and durability.

- Housing: Cast iron for heavy-duty applications or aluminum for a lighter, more compact design.

- Seals and Bearings: High-grade elastomers and bearings that can handle the operating pressures and temperatures typical in hydraulic systems.

3P Series hydraulic gear pumps are characterized by their robust operational features:

- Variable Displacement: These pumps can adjust flow rates to match system demands, enhancing efficiency and reducing energy consumption.

- High Pressure Capability: Designed to operate at medium to high pressures, making them suitable for demanding applications.

- Efficiency: Advanced gear designs and high-quality materials ensure high volumetric efficiency, minimizing internal leakage and maximizing performance.

- Quiet Operation: The use of helical gears and precision manufacturing techniques results in quieter operation compared to standard gear pumps.

3P Series hydraulic gear pumps are versatile, Common applications include:

- Industrial Machinery: Used in hydraulic systems for manufacturing and processing equipment where consistent and high-pressure fluid flow is required.

- Construction Equipment: Powers hydraulic systems in heavy machinery such as excavators, loaders, and cranes, which operate under demanding conditions.

- Agriculture: Utilized in hydraulic systems for tractors, harvesters, and other farming equipment that require robust and reliable performance.

- Automotive: Employed in power steering systems, transmissions, and lubrication systems in vehicles.

- Marine: Used in hydraulic systems for steering, winching, and other onboard machinery, where reliability and efficiency are crucial.

How Hydraulic Gear Pumps Work

Hydraulic gear pumps work by using the meshing action of the gear set to create a vacuum that draws fluid into the pump. The fluid is then carried between the teeth of the gears and forced out through the outlet port. The gear set is designed in such a way that the teeth of one gear mesh with the teeth of the other gear, which creates a sealed chamber between the teeth. As the gears rotate, the chamber moves from the inlet port to the outlet port, which forces the fluid out of the pump.

One of the advantages of hydraulic gear pumps is that they are relatively simple in design and can be manufactured at a relatively low cost. They are also very efficient and can generate a high volume of fluid flow in a short period of time. However, there are some limitations to the use of hydraulic gear pumps. For example, they are not very effective at handling fluids with high viscosities, and they can be noisy and prone to wear and tear over time.

Classification of Hydraulic Gear Pumps

Hydraulic gear pumps can be classified into two main categories : external pumps and internal pumps.

External Gear Pumps: External pumps are the most common type of hydraulic gear pump. They consist of two gears that mesh together outside of the pump housing. The gear set is contained in a casing that is bolted to the pump housing. External gear pumps are known for their simplicity, reliability, and low cost.

Internal Gear Pumps: Internal pumps are less common than external gear pumps, but they are still used in some applications. They consist of an outer gear and an inner gear that mesh together inside the pump housing. The inner gear is connected to the drive shaft, while the outer gear is stationary. Internal gear pumps are typically more expensive than external gear pumps, but they are also more efficient and can handle higher fluid pressures.

Applications of Hydraulic Gear Pumps

These pumps are used in a variety of applications, including:

- Construction Equipment: These are used in construction equipment such as backhoes, excavators, and bulldozers. They are used to power the hydraulic systems that operate the various functions of the equipment.

- Agricultural Machinery: These pumps are also used in agricultural machinery such as tractors, combines, and harvesters. They are used to power the hydraulic systems that control the various functions of the machinery, such as lifting and lowering the equipment.

- Industrial Machinery: These pumps are used in industrial machinery such as presses, stamp

Precautions - While Running A Hydraulic Gear Pump

Make sure that the hydraulic gear pump rotation matches the drive shaft direction. Keep correct alignment between pump and motor shafts to avoid axial or radial stress. Protect the Drive Shaft Seal when painting, and make sure all attachment points are free from dust or debris. The pump must always be mounted beneath the liquid level as shown with both suction and discharge lines flooded. Prime the pump with oil before starting up, eliminate air from the system… then move gradually up to pressure and temperature checks that will make sure Hydrofit Engineers can provide you with efficient service.

Drive shaft seal should be protected during painting of the pump body.The contact area between the seal ring and the shaft should be clean. Dust and dirt can cause faster wear and leakage in the pump. Dust and dirt and foreign bodies should be cleaned from connecting inlet and outlet parts.