Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

HYDRAULIC ACCESSORIES

Hydraulic accessories are components that are used in conjunction with hydraulic systems to perform various functions, such as control, measurement, and maintenance

Single Pilot Check Valve

Double Pilot Check Valve

Multistation Gauge Isolator

Flexible Drive Coupling

A flexible drive coupling is one of a type of hydraulic accessories that connects two shafts in a hydraulic system, accommodating slight misalignments and reducing transmission of shock loads and vibrations. This coupling ensures smooth power transmission while protecting components from excessive wear and damage. Made from materials like rubber or flexible composites, it enhances the longevity and efficiency of machinery by absorbing mechanical stresses.

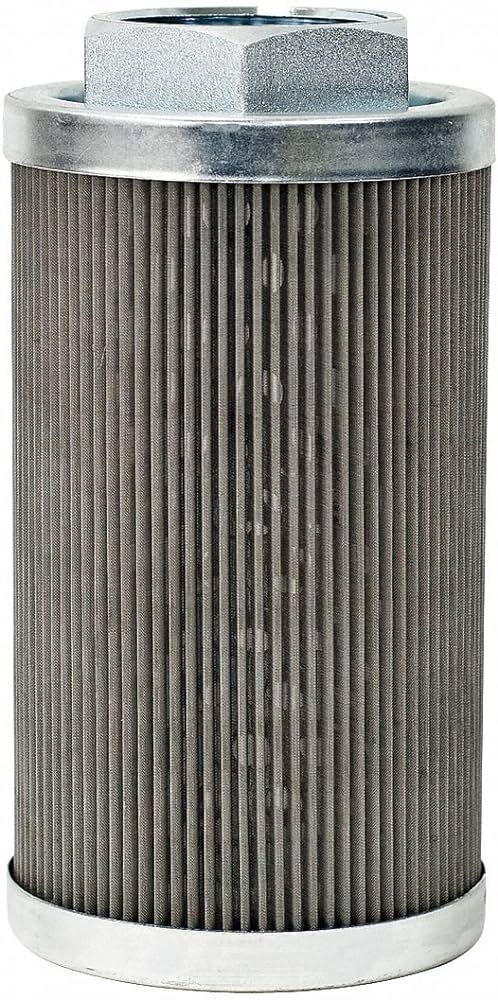

Suction Strainer

A suction line filter is one of a type of hydraulic accessories that is installed in the hydraulic system’s intake line to protect the pump by removing contaminants from the hydraulic fluid before it enters the pump. It typically features a coarse filter element that traps larger particles, ensuring that only clean fluid is circulated within the system. This preventative measure extends the life of the pump and other hydraulic components.

Filler Breather

A filler breather is a dual-function component used in hydraulic systems. It one of a type of hydraulic accessories that allows for the addition of hydraulic fluid to the reservoir while also providing a venting mechanism to equalize pressure and prevent contaminants from entering. Equipped with a filter element, it ensures that air entering the system is clean, thereby maintaining the purity and performance of the hydraulic fluid

Fluid Level Gauge

A fluid level gauge is an essential device in hydraulic systems, used to monitor and display the fluid level within a reservoir. It one of a type of hydraulic accessories that helps operators ensure that the hydraulic fluid remains at an optimal level, preventing potential damage caused by low fluid levels or overfilling. These gauges often feature a clear sight tube or a digital display for easy readability. They are crucial for maintaining system efficiency and avoiding operational disruptions in various industrial and mobile hydraulic applications

Return Line Filter

A return line filter is positioned in the return line of a hydraulic system to capture contaminants from the hydraulic fluid before it returns to the reservoir. It helps maintain fluid cleanliness and protects system components from wear and damage. Equipped with fine filter elements, it ensures that any debris generated during operation is effectively removed, promoting system reliability and efficiency

Pressure Line Filter

A pressure line filter is installed in the hydraulic system’s pressure line to remove contaminants from the hydraulic fluid before it reaches sensitive components like valves and actuators. Equipped with fine filter elements, these filters ensure the delivery of clean fluid under high pressure, protecting system components from wear and extending their lifespan. Pressure line filters are vital in high-demand applications, such as industrial machinery and construction equipment, where maintaining fluid purity is essential for reliable performance

Inline Filter

An inline filter is a versatile component used in hydraulic systems to remove contaminants from the hydraulic fluid as it flows through the system. Installed directly in the fluid line, these filters can be used in various locations, such as suction, pressure, or return lines. They help maintain fluid cleanliness, protect critical components, and enhance overall system reliability. Inline filters are commonly used in industrial machinery, automotive systems, and other applications where space constraints and ease of maintenance are important considerations.

Threaded Breather

A threaded breather is a type of air venting device used in hydraulic reservoirs to equalize internal and external pressures while preventing contaminants from entering the system. Screwed directly into the reservoir, it features a filtering element that blocks dust, dirt, and moisture. By maintaining a clean and pressure-balanced environment, threaded breathers help ensure the optimal performance and longevity of hydraulic systems. They are widely used in industrial equipment, mobile machinery, and other applications where maintaining fluid purity is crucial

Single Station Gauge Isolator

A single station gauge isolator is a hydraulic device used to protect pressure gauges by isolating them from the system pressure when not in use. This prevents potential damage due to continuous exposure to high pressure and pulsations. It allows the gauge to be engaged only when readings are needed, ensuring accurate measurements and extending the gauge’s lifespan. Single station gauge isolators are commonly used in industrial hydraulic systems to maintain measurement accuracy and equipment reliability.

Multistation Gauge Isolator

A multistation gauge isolator allows multiple pressure gauges to be connected and selectively isolated in a hydraulic system. It enables monitoring of different pressure points using a single gauge, enhancing system diagnostics and maintenance efficiency. By isolating unused gauges, it protects them from continuous pressure exposure and potential damage. Multistation gauge isolators are ideal for complex hydraulic systems in industrial and mobile applications, where precise pressure monitoring at various points is essential for optimal performance

Single Pilot Check Valve

A single pilot check valve is a hydraulic component that allows fluid flow in one direction and blocks it in the opposite direction until a pilot pressure is applied. It ensures that the fluid flow remains controlled and prevents backflow, enhancing system stability and safety. When pilot pressure is introduced, the valve opens to permit flow in both directions. Single pilot check valves are commonly used in hydraulic circuits requiring secure holding and controlled movement, such as in hydraulic cylinders.

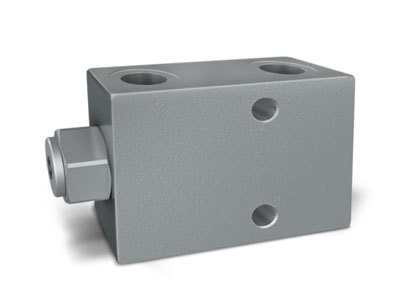

Double Pilot Check Valve

A Double Pilot Check Valve is one of a type of hydraulic accessories that operates similarly to a single pilot check valve but with two pilot lines, allowing controlled fluid flow in both directions. It locks the fluid in the circuit, preventing movement until pilot pressure is applied to either side, ensuring secure and precise control. This dual functionality is ideal for applications requiring bidirectional control and safety, such as in hydraulic lifting and clamping systems. Double pilot check valves enhance the reliability and flexibility of hydraulic systems in industrial and mobile machinery

Other Hydraulic Accessories

Some common other hydraulic accessories include:

Hydraulic hoses and fittings – These are used to connect hydraulic components, such as pumps, valves, and cylinders, together in a hydraulic system. They are typically made of flexible materials, such as rubber or thermoplastic, and come in a variety of sizes and configurations.

- Pressure gauges – These are used to measure the pressure of the hydraulic fluid in the system. They are typically mounted on the hydraulic pump or valve and provide the operator with a visual indication of the system pressure.

- Flow meters – These are used to measure the flow rate of the hydraulic fluid in the system. They are typically installed in the hydraulic line and provide the operator with a visual indication of the flow rate.

- Filters – These are used to remove contaminants, such as dirt and debris, from the hydraulic fluid. They are typically installed in the hydraulic line or in the hydraulic reservoir and help to keep the system running smoothly.

- Accumulators – These are used to store hydraulic fluid under pressure, which can be released to perform work when needed. They are typically used in applications where rapid movement is required, such as in heavy equipment or manufacturing machinery.

- Relief valves – These are used to limit the maximum pressure in the hydraulic system. They are typically installed in the hydraulic pump or valve and provide a safety mechanism to prevent damage to the system or equipment.

Overall, hydraulic accessories are essential components of hydraulic systems and play an important role in ensuring the safe and efficient operation of the equipment.

These are used to connect hydraulic components, such as pumps, valves, and cylinders, together in a hydraulic system. They are typically made of flexible materials, such as rubber or thermoplastic, and come in a variety of sizes and configurations