Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Camlock Couplings

Camlock couplings, also known as cam and groove couplings, are quick-connect fittings designed for easy and rapid connection and disconnection of hoses, pipes, and other fluid-handling equipment. They consist of two main parts: a male adapter (with a protruding cam arm) and a female coupler (with a recessed area and a cam arm). The cam arms are used to lock the two halves together, providing a secure and leak-proof connection. These couplings are widely used in various industries for fluid transfer applications.

Why use Camlock Couplings

Here are the key features and some reasons why to use Camlock Couplings

- Quick and Easy Connection:

- One of the primary advantages of camlock couplings is their ability to provide quick and easy connections without the need for tools. This is particularly beneficial in applications where speed and efficiency are crucial.

- Versatility:

- Camlock couplings come in different types (Type A, B, C, D, E, F, and DC), each designed for specific connection requirements. This versatility allows for compatibility and interchangeability within a system.

- Wide Range of Sizes:

- They are available in various sizes, accommodating different hose and pipe dimensions. This ensures flexibility in adapting to various system requirements.

- Interchangeability:

- The different types of camlock couplings are designed to be compatible with each other. This interchangeability allows users to connect different equipment easily within a system.

- Leak Prevention:

- Camlock couplings incorporate gaskets or seals to prevent leakage during fluid transfer. When properly installed and maintained, they provide a reliable and tight seal.

- Durability and Materials:

- Camlock couplings are available in a variety of materials, including stainless steel, aluminum, brass, polypropylene, and others. The choice of material depends on the application and the nature of the fluids being transferred.

- Reduced Risk of Cross-Contamination:

- The design of camlock couplings helps minimize the risk of cross-contamination between different fluids. This is particularly important in applications where maintaining the purity of the transferred material is critical.

- Ease of Handling:

- The handles or levers on camlock couplings make them easy to handle and operate, even in challenging or confined spaces. This ease of use contributes to the overall efficiency of fluid transfer processes.

- Cost-Effective:

- Camlock couplings are relatively simple in design and easy to manufacture, contributing to their cost-effectiveness. They provide a reliable solution for fluid transfer without the need for complex or expensive equipment.

- Used Across Industries:

- Camlock couplings find applications in a wide range of industries, including manufacturing, petrochemicals, agriculture, food and beverage, pharmaceuticals, water treatment, and more.

In summary, camlock couplings are chosen for their speed, simplicity, and versatility in connecting and disconnecting hoses and pipes for fluid transfer. Their widespread use across diverse industries speaks to their effectiveness and reliability in various applications.

Design and Construction of Camlock Couplings

The design and construction of camlock couplings involve several key elements to ensure efficient and secure fluid transfer. Here’s an overview of the typical components and considerations involved in the design and construction of camlock couplings:

- Materials:

- Body Material: Camlock couplings can be made from various materials, including stainless steel, aluminum, brass, and polypropylene. The material choice depends on factors such as the type of fluid being transferred, environmental conditions, and compatibility with the application.

- Cam Arms:

- Design: Cam arms are a crucial component that allows for the quick and secure connection of the male and female parts of the coupling. The design of the cam arms should ensure a tight and leak-free connection.

- Handles/Levers: Cam arms are often equipped with handles or levers for easy operation. These handles facilitate the quick engagement and disengagement of the coupling.

- Seals and Gaskets:

- Material: Seals and gaskets are used to prevent leakage during fluid transfer. The material of the seals should be chosen based on compatibility with the fluids being handled.

- Placement: Seals are strategically placed in areas where fluid transfer occurs, ensuring a tight seal when the coupling is connected.

- Locking Mechanism:

- Spring Mechanism: Some camlock couplings incorporate spring mechanisms in the cam arms to maintain a secure connection by exerting pressure on the sealing surfaces.

- Locking Features: The design may include additional features to enhance the locking mechanism and prevent unintentional disconnection.

- Connection Types:

- Types A to F: Camlock couplings come in various types (A to F) to accommodate different connection requirements. These types ensure compatibility between different couplings within a system.

- Size and Dimensions:

- Standard Sizing: Camlock couplings are available in standard sizes to match the dimensions of hoses, pipes, and other fluid-handling equipment. Standard sizing ensures compatibility and interchangeability.

- Finish and Coating:

- Corrosion Resistance: Depending on the application, the couplings may have finishes or coatings to enhance corrosion resistance, especially when the coupling is made from metals like steel or aluminum.

- Testing and Standards:

- Quality Assurance: Manufacturers often conduct testing to ensure the quality and reliability of camlock couplings. Compliance with industry standards and regulations is essential.

- Application-Specific Considerations:

- Chemical Compatibility: The design should account for the compatibility of materials with the specific chemicals or fluids being transferred.

- Temperature and Pressure Ratings: The design should consider the temperature and pressure conditions of the application to ensure the couplings can handle the intended operating temperature and pressure ratings.

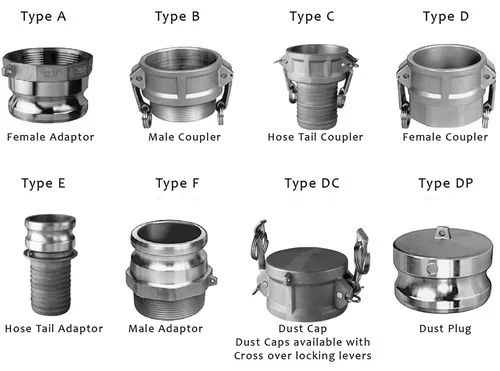

Types of Camlock Couplings and their uses

The most commonly used type of camlock coupling depends on the specific industry, application, and the requirements of the fluid transfer. Camlock couplings come in various types, each designated by a letter (Type A, B, C, D, E, F, and DC). Here’s a brief overview of some commonly used types:

- Type A:

- Description: Type A couplings have a male adapter with a smooth hose shank and cam arms.

- Common Use: Widely used in industries such as agriculture, water delivery, and general-purpose fluid transfer.

- Type B:

- Description: Type B couplings have a female coupler with cam arms and a smooth hose shank.

- Common Use: Commonly used for quick connections in various applications, including water, chemicals, and petroleum.

- Type C:

- Description: Type C couplings have a female coupler with cam arms and a serrated hose shank.

- Common Use: Suitable for applications where a more secure connection is required, such as with hoses that have a more rigid construction.

- Type D:

- Description: Type D couplings have a female coupler with cam arms and a female thread.

- Common Use: Used when a threaded connection is required, often in industrial settings for connecting pipes or equipment.

- Type E:

- Description: Type E couplings have a male adapter with cam arms and a hose shank with external threads.

- Common Use: Found in applications where a male-threaded connection is needed.

- Type F:

- Description: Type F couplings have a male adapter with cam arms and a male thread.

- Common Use: Used in applications requiring a male-threaded connection, such as connecting to pipes or equipment.

- Type DC (Dust Cap):

- Description: Type DC couplings are dust caps that fit over the male or female end to protect against contaminants when not in use.

- Common Use: Used as protective caps to prevent dust and debris from entering the system during storage or transport.

The most commonly used type can vary based on regional preferences, industry standards, and specific applications. In many cases, Type A and Type B couplings are widely adopted due to their versatility and ease of use in a broad range of applications. However, the choice ultimately depends on the unique requirements of each application

Material of Construction of Camlock Couplings

The Material of Construction (MOC) for camlock-couplings varies based on the application, the type of fluid being transferred, environmental conditions, and other factors. Here are common materials of construction used for camlock couplings:

- Stainless Steel:

- Advantages: Stainless steel is known for its corrosion resistance, durability, and strength. It is suitable for a wide range of applications, including those involving corrosive chemicals or where hygiene is crucial.

- Applications: Stainless steel camlock couplings are commonly used in industries such as pharmaceuticals, chemicals, food and beverage, and marine.

- Aluminum:

- Advantages: Aluminum is lightweight, corrosion-resistant, and offers good strength. It is often used in applications where weight is a concern and where moderate corrosion resistance is sufficient.

- Applications: Aluminum camlock couplings are found in industries such as agriculture, water delivery, and certain chemical applications.

- Brass:

- Advantages: Brass is corrosion-resistant, provides good conductivity, and has antimicrobial properties. It is commonly used in applications where these properties are important.

- Applications: Brass camlock couplings find use in water distribution, pneumatic systems, and some chemical transfer applications.

- Polypropylene:

- Advantages: Polypropylene is a thermoplastic known for its chemical resistance and lightweight properties. It is often used in applications involving a variety of chemicals and acids.

- Applications: Polypropylene camlock couplings are used in chemical processing, agriculture, and other industries where resistance to chemical corrosion is crucial.

- Nylon:

- Advantages: Nylon is a lightweight and strong thermoplastic with good chemical resistance. It is suitable for applications requiring flexibility and impact resistance.

- Applications: Nylon camlock couplings are used in water distribution, irrigation, and certain chemical transfer applications.

- PTFE (Polytetrafluoroethylene):

- Advantages: PTFE is known for its excellent chemical resistance and non-stick properties. It is suitable for applications involving highly corrosive or aggressive chemicals.

- Applications: PTFE camlock couplings are used in the chemical and pharmaceutical industries.

The choice of material depends on factors such as the nature of the fluid being transferred, temperature and pressure conditions, compatibility with other materials in the system, and regulatory requirements. It’s important to select the appropriate Material of Construction for camlock couplings to ensure optimal performance and safety in a given applicatio-

Advantages of Camlock Couplings

Camlock-couplings offer several advantages that make them popular in various industries for fluid transfer applications. Here are some key advantages of camlock couplings:

- Quick and Easy Connection:

- Camlock-couplings are designed for rapid connection and disconnection without the need for tools. This feature significantly reduces downtime during fluid transfer operations.

- Versatility:

- They come in various types (A to F) to accommodate different connection requirements. This versatility allows for compatibility and interchangeability within a system.

- Wide Range of Sizes:

- Camlock-couplings are available in a wide range of sizes to match the dimensions of hoses, pipes, and other fluid-handling equipment. This ensures flexibility in adapting to various system requirements.

- Compatibility:

- The different types of camlock-couplings are designed to be compatible with each other, enabling users to connect different equipment easily. This interchangeability enhances the flexibility of system configurations.

- Leak Prevention:

- Camlock-couplings incorporate gaskets or seals to prevent leakage during fluid transfer. Properly installed and maintained, they offer a reliable and tight seal.

- Durable Construction:

- Depending on the material of construction (e.g., stainless steel, aluminum, polypropylene), camlock couplings can be durable and resistant to corrosion, ensuring a long service life even in challenging environments.

- Reduced Risk of Cross-Contamination:

- The design of these couplings helps minimize the risk of cross-contamination between different fluids. This is particularly important in applications where maintaining the purity of the transferred material is critical.

- Ease of Handling:

- The handles or levers on these couplings make them easy to handle and operate, even in challenging or confined spaces. This ease of use contributes to the overall efficiency of fluid transfer processes.

- Variety of Materials:

- Camlock couplings are available in various materials, including stainless steel, aluminum, brass, polypropylene, and more. This allows users to select the material that best suits the specific requirements of their application.

- Cost-Effective:

- The simplicity of the design and ease of manufacturing contribute to the cost-effectiveness of camlock couplings. They provide a reliable solution for fluid transfer without the need for complex or expensive equipment.

- Used Across Industries:

- Camlock couplings find applications in a wide range of industries, including manufacturing, petrochemical, agriculture, food and beverage, pharmaceuticals, and more. Their adaptability makes them suitable for diverse environments.

While camlock couplings offer numerous advantages, it’s important to consider factors such as material compatibility, temperature and pressure requirements, and adherence to safety standards when selecting and using them in specific applications.these

Applications of Camlock Couplings

Camlock couplings find applications across various industries due to their versatility, quick-connect features, and ease of use. Here are some common applications of camlock couplings:

- Chemical Industry:

- Used for the transfer of chemicals and corrosive substances. Different materials of construction are selected based on the compatibility with specific chemicals.

- Petrochemical Industry:

- Applied in the transfer of petroleum products, oils, and other hydrocarbons. Camlock couplings are often used for loading and unloading tanker trucks.

- Manufacturing and Industrial Processes:

- Employed in manufacturing processes for the quick connection of hoses and pipes, facilitating fluid transfer between different stages of production.

- Agriculture:

- Used in agriculture for irrigation systems, water pumps, and the transfer of fertilizers, pesticides, and other agricultural chemicals.

- Food and Beverage Industry:

- Applied in the transfer of food products, beverages, and liquid ingredients. Stainless steel camlock couplings are commonly used to meet hygiene and sanitary standards.

- Pharmaceutical Industry:

- Used for the transfer of pharmaceutical liquids and chemicals. Camlock couplings made from materials like stainless steel or PTFE are chosen for their compatibility with pharmaceutical processes.

- Water Treatment:

- Employed in water treatment plants for the connection of hoses and pipes in processes such as water purification, distribution, and wastewater treatment.

- Mining Industry:

- Used in mining operations for the transfer of water, chemicals, and slurry. Camlock couplings are chosen for their durability in challenging environments.

- Oil and Gas Industry:

- Applied in various stages of oil and gas exploration, production, and transportation for the transfer of fluids, including crude oil, natural gas, and drilling fluids.

- Transportation and Logistics:

- Utilized for the quick loading and unloading of tanker trucks and railcars, especially in the transportation of bulk liquids.

- Firefighting:

- Used in firefighting equipment for the rapid connection of hoses, allowing for efficient deployment during emergencies.

- HVAC (Heating, Ventilation, and Air Conditioning):

- Employed in HVAC systems for the connection of hoses and pipes used in the transfer of coolants, water, and other fluids.

- Construction Sites:

- Applied in construction sites for the quick connection and disconnection of hoses used in concrete pumping, dewatering, and other construction-related processes.

- Military and Defense:

- Utilized for various fluid transfer applications in military operations, including fueling, water supply, and equipment maintenance.

- Emergency Response:

- Camlock couplings are used in emergency response situations for the quick setup and connection of hoses during disaster relief efforts.

The versatility and efficiency of camlock couplings make them suitable for a wide range of applications, and their use continues to expand across diverse industries.