Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

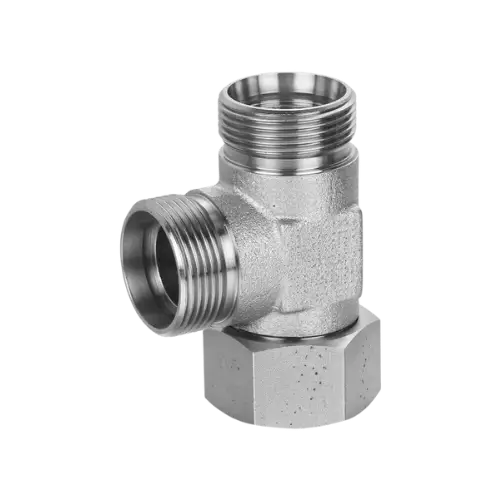

Hydraulic Swivel Tee

Hydrofit Engineers is a trusted supplier of high-performance hydraulic swivel tee designed for precision, durability, and reliability in demanding industrial environments. With a strong focus on quality and performance, Hydrofit Engineers ensures every fitting meets rigorous standards, offering efficient solutions for complex hydraulic systems across construction, agriculture, and manufacturing sectors.

Hydraulic Swivel Tee Components

The hydraulic swivel tee is made from 3 individual pieces: male fitting, female fitting and the swivel joint.

The male and female fittings are connected to two of the hydraulic hoses or pipes, with the swivel joint being attached to the third. The two fittings are releasably secured to one another by means of the swivel joint to permit flexure between hoses or pipes.

There are certain components that comprises a swivel joint for a swivel tee, such as bearing, seal and retaining ring. The bearing is typically a ball or roller bearing, which permits smooth rotation between the fittings and the seal acts to prevent leakage of fluid out of the joint. The bearing and seal are retained by the retaining ring.

Types of Hydraulic Swivel Tee

There are different variants of hydraulic swivel tee available, each of them produced with specific requirements of action in mind.

It is important to note that the most common use is just to maintain a rotational device like conduits, hose or pipes but with more flexibility based on performance requirements and pressure/torque telemetry through the tee It should also be noted here that for swivel tees there are several things to keep an eye out for hoses or pipe size, size of flow (which mean ID of the swivel), fluid type being transferred, assembly working force torque being applied and materials used in construction.

A popular configuration of the hydraulic swivel tee is one that is 90 degrees. This tee is designed to accept 3 hoses or pipes at a 90 angle and permit flow between them. Typically used for connecting hoses and pipes at 90 degree angle, for example in the hydraulic breaker (construction equipment as mentioned above).

Another popular style of hydraulic swivel tee is the 45 degree swivel tee. This tee has three openings at a 45 degree angle to connect and branch three pipes or hose While keeping one connection stationary, this rotating tee changes the direction of flow as it allows you to rotate each outlet nozzel. 45 degree swivel tees are commonly utilized when the hoses or pipes need to be attached at a certain angle, for example in hydraulic systems on agricultural equipment.

This hydraulic swivel tee is the straight through swivel tee. This type of tee is used to connect three hoses or pipes in a straight line and may capable of rotating on the middle axis. Straight swivel tees are commonly found in applications where the hoses or pipes must be connected straight, but might experience twisting or bending.

Contruction Material

Along with the various types of swivel tees available, there are also many different materials from which they can be made. The most popular types of material used for production are brass, steel, and stainless steel. Explore our extensive range of hydraulic fittings in Chennai for complete connection solutions.

The material employed will be selected based on the requirements of the application, including, but not limited to fluid being transferred and system operating parameters.

How To Choose Right Swivel Tee for Hydraulic system

While choosing a hydraulic swivel tee, there are several factors to take into account in order for the tee to adequately accommodate the application’s requirements. A few big things to think about are:

Size: The size of the swivel tee should accommodate the size of the hoses or lines that you are connecting together. The wrong size can cause leaks or other problems.

Pressure Handling: pressure of hydraulic system which the swivel tee can handle. Selecting a tee with an inferior pressure rating can cause system failure or damage.

Type of fluid: make sure that the swivel tee is compatible with the type of liquid transferring. Selecting a tee that is not compatible might cause corrosion or other concerns.

Operating conditions: The swivel tee should be appropriate for the operating condition of the system, corridor temperature/humidity etc and any potential environmental exposure. Discover our premium-quality quick release couplings engineered for easy connection and seamless hydraulic performance.