Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

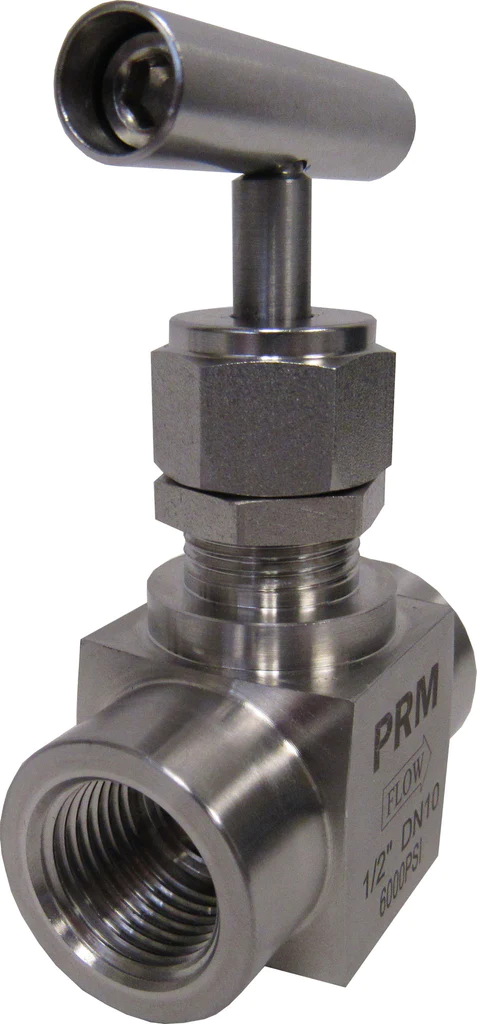

HIGH PRESSURE NEEDLE VALVE

A high pressure needle valve is a type of high pressure valve that is designed to regulate the flow of fluids or gases at high pressures. It is typically used in industrial applications where precision flow control is required, such as in the oil and gas industry, chemical processing, and high-pressure testing.

The valve gets its name from the shape of its internal components, which resemble a needle. The valve has a slender, tapered stem that is threaded at the top, and a small orifice at the bottom that is surrounded by a tapered seat. When the stem is turned, the tapered end of the stem moves closer to or further away from the seat, controlling the flow of fluid or gas through the orifice.

High pressure needle valves are made from durable materials such as stainless steel, brass, or carbon steel, and are designed to withstand the high pressures and temperatures associated with industrial applications. They come in a variety of sizes and configurations, including straight, angled, and multi-port versions, and can be operated manually or with pneumatic or electric actuators.

Inline Needle Valve - BSP

Inline RA Needle Valve - BSP

A high pressure needle valve is a type of valve that is designed to handle high pressure fluids and gases. It is commonly used in applications such as oil and gas production, chemical processing, and power generation. In this article, we will discuss the features, benefits, and applications of high pressure needle valves.

Features of High Pressure Needle Valve

A High Pressure Needle valve is commonly used in applications such as oil and gas production, chemical processing, and power generation.

High pressure needle valves are designed to handle pressures that are significantly higher than those typically seen in standard valves. They typically have a maximum working pressure of 10,000 psi or more. The valve body is usually made from high-strength materials such as stainless steel or titanium to withstand high pressures.

One of the key features of a high pressure needle valve is its ability to provide precise control over the flow rate of fluids and gases. The valve has a long, tapered needle-shaped stem that is threaded into the valve seat. When the valve is opened, the stem is lifted away from the seat, allowing the fluid or gas to flow through the valve. By adjusting the position of the stem relative to the seat, the flow rate can be controlled with a high degree of accuracy.

Another important feature of these valves is their ability to withstand high temperatures. They are often used in high-temperature applications such as steam systems and chemical reactors. The valve stem and seat are designed to withstand temperatures of up to 500°F or more.

Benefits of High Pressure Needle Valve

The precise control over flow rate offered by these valves provides a number of benefits in industrial applications. Some of the key benefits include:

Improved efficiency: By providing precise control over the flow rate of fluids and gases, these valves can help improve the efficiency of industrial processes. This can lead to cost savings and increased productivity.

Enhanced safety: These valves are designed to withstand high pressures and temperatures, which can help prevent leaks and other types of failures that can pose safety hazards in industrial settings.

Increased accuracy: The precise control over flow rate offered by these valves can help improve the accuracy of industrial processes, which is particularly important in applications such as chemical processing where small changes in flow rate can have significant effects on the outcome of the process.

Reduced maintenance: These valves are designed to be durable and long-lasting, which can help reduce the need for maintenance and repair over time.

Applications of High Pressure Needle Valve

These valves are used in a wide range of industrial applications. Some of the most common applications include:

Oil and gas production: These needle valves are used in oil and gas production to control the flow of fluids in pipelines, wellheads, and other parts of the production process.

Chemical processing: These valves are used in chemical processing to control the flow of fluids and gases in reactors, distillation columns, and other parts of the process.

Power generation: These valves are used in power generation to control the flow of steam and other fluids in turbines, boilers, and other parts of the power plant.

Aerospace: These valves are used in aerospace applications such as rocket engines and jet propulsion systems to control the flow of fuel and other fluids.

Medical equipment: These valves are used in medical equipment such as ventilators and oxygen therapy systems to control the flow of gases.

In summary, these HP valves are an important component in a wide range of industrial applications where precise control over the flow rate of fluids and gases is required. They offer a number of benefits, including improved efficiency, enhanced safety, increased accuracy, and reduced maintenance. With their ability to handle high pressures and temperatures, high pressure needle valves are an essential tool for many industries

For very high pressure and critical applications MAXPRO Valves offer a good solution with their range of ultra high pressure Needle Valves