A three-valve manifold is an essential component of process control instrumentation used in industries such as oil and gas, chemical, and pharmaceuticals. It provides a means of isolating pressure instruments from the process, which is critical for calibration, maintenance, and repair purposes. The SS 3 valve manifold is a variant of the three-valve manifold made of stainless steel material and is designed to withstand harsh environmental conditions.

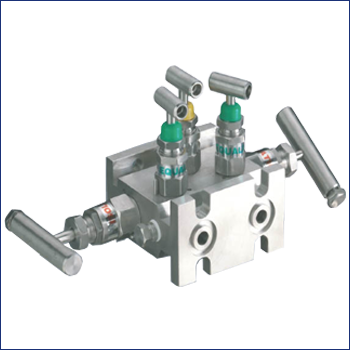

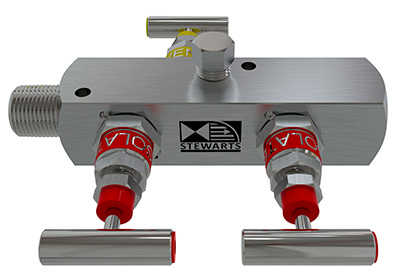

The SS 3 valve manifold comprises three valves and two process connections, all connected through a common body. The three valves include two block valves and one equalizing valve. The block valves are used to isolate the instrument from the process, while the equalizing valve is used to equalize the pressure between the high and low-pressure sides of the instrument.

The SS 3 valve manifold is typically used in applications where the process fluid is corrosive, viscous, or contains solids. The stainless steel material used to make the manifold is resistant to corrosion, rust, and degradation. This makes it suitable for use in harsh and corrosive environments.

The SS 3 valve manifold has several advantages over other types of manifolds. These include:

Durability – The stainless steel material used to make the manifold is durable and resistant to corrosion, rust, and degradation. This makes it suitable for use in harsh and corrosive environments.

Safety – The SS 3 valve manifold provides a means of isolating the instrument from the process, which is critical for safety purposes. The block valves can be used to shut off the flow of the process fluid to the instrument, while the equalizing valve can be used to equalize the pressure between the high and low-pressure sides of the instrument.

Reliability – The SS 3 valve manifold is designed to be reliable and requires minimal maintenance. The valves are designed to operate smoothly and without leaks, and the manifold is designed to withstand high pressures and temperatures.

Easy Installation – The SS 3 valve manifold is easy to install and can be configured to meet specific application requirements. It is available in different configurations and can be easily connected to the instrument and process piping.

The SS 3 valve manifold is an essential component of process control instrumentation used in industries such as oil and gas, chemical, and pharmaceuticals. It provides a means of isolating pressure instruments from the process, which is critical for calibration, maintenance, and repair purposes. The manifold is made of generally Stainless Steel 304 or Stainless Grade Material. It is available in two types – Remote operated type and Integral Type models.