Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

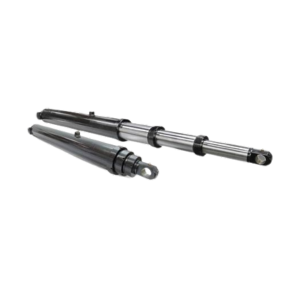

Pneumatic Telescopic Cylinder

Multi-Stage Telescoping Air Actuators

Hydrofit’s pneumatic telescopic cylinders deliver extended stroke and minimal retracted length – made for aerial platforms, dump beds, material handling and mobile equipment. Available in single-acting and double-acting configurations with adjustable stage counts and bore diameters.

Why Choose Hydrofit Pneumatic Telescopic Cylinders

- Commercial-grade, multi-stage design for long stroke with compact retracted length.

- Single-acting (spring/retract) and double-acting options.

- Industry-grade sealing & surface treatments for durability in mobile and industrial environments.

- Customizable stroke and stage configuration – build-to-order SKU support.

Product Configurations & Use Cases

You will get adjustable telescopic air cylinders for: aerial platforms, dump trucks, dock levelers, material handling systems, agricultural implements and compact construction equipment which are optimized to meet duty cycle and environmental requirements.

Aerial platforms & cherry pickers

(long stroke, compact storage)

Active dump beds & trailers

(robust single/double acting lift)

Dock levelling & material handling

(synchronized multi-cylinder arrays)

Technical Features & Benefits of Telescopic Cylinders

- Nested multi-stage design for maximum stroke-to-retracted length ratio.

- High-integrity seals and low-friction coatings for long service life.

- Optional encoders/position sensors and locking features for safety-critical lifts.

- Modular mounting (flange, trunnion, clevis) for OEM integration.

want to place order for Pneumatic telescopic cylinder?

We’re just a call away

FAQs

1. What is the lead time for custom pneumatic telescopic cylinders?

Typically, the lead time for custom builds is 7–14 business days.

2. Can I order single prototype units?

Yes, Hydrofit accommodates prototype orders and quantity-based pricing for production runs.

3. What is the maximum stroke available?

Standard telescopic strokes reach up to 1200 mm with multi-stage assemblies. you can consult to Hydrofit for large-stroke custom designs.

4. How to select a pneumatic telescopic cylinder?

Choose by specifying the following parameters:

load, stroke, retracted envelope, acting type, bore/pressure, duty cycle, environment, mounting, and compliance.

For customized specifications, ask for a Hydrofit sizing consultation or you know more about telescoping cylinders here.

5. How many type of pneumatic cylinder you deliver?

Hydrofit Engineers supplies telescopic, single-acting, double-acting, rodless, guided/tie-rod, compact, heavy-duty cylinders, plus custom integrated solutions.