Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Hydraulic Solenoid Valve

Hydraulic solenoid valves are the cornerstone of modern hydraulic systems – providing precise, automated control over the flow and direction of hydraulic fluid. These valves convert electrical energy into mechanical motion, allowing machinery to operate with accuracy, efficiency, and safety.

At Hydrofit Engineers, we specialize in designing and delivering high-performance hydraulic solenoid valves and more other hydraulic valves that enhance automation and reliability across industries.

What is a Hydraulic Solenoid Valve?

A hydraulic solenoid valve is an electromechanically operated directional control valve that manages the flow of pressurized fluid within a hydraulic circuit. When energized, the solenoid coil generates a magnetic field that moves a spool or plunger, opening or closing specific ports to direct the hydraulic fluid precisely where it’s needed.

These valves are vital for controlling actuators, motors, and cylinders – making them indispensable in automation, heavy machinery, and industrial systems.

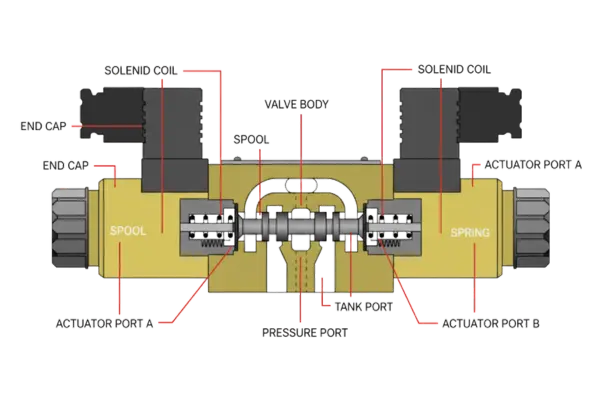

Construction and Key Components

A typical hydraulic solenoid valve is engineered for performance and durability under high pressure. The main components include:

- Solenoid Coil: Generates the magnetic field required to actuate the valve.

- Armature (Plunger): A movable component that shifts in response to the magnetic field.

- Valve Body: A robust structure, usually made of stainless steel or cast iron, containing ports and fluid channels.

- Spring Return: Ensures the spool returns to its original position when the solenoid is de-energized.

- Seals: Made of NBR, Viton, or EPDM to prevent leakage and maintain pressure integrity.

- Ports (P, A, B, T): Directs the flow of hydraulic fluid through pressure, working, and return lines.

Working Principle of Hydraulic Solenoid Valves

The working of a hydraulic solenoid valve is based on electromagnetic actuation.

- Energizing the Coil: When electrical current passes through the solenoid, it generates a magnetic field.

- Spool Movement: The magnetic force pulls or pushes the spool/armature, opening or closing specific ports.

- Fluid Direction: Hydraulic fluid flows through the open paths to the desired actuator or returns to the tank.

- De-energizing: When power is cut off, the spring mechanism resets the spool to its default position.

This precise switching action ensures controlled, repeatable operation across high-pressure hydraulic circuits. know more about solenoid valve here.

4/3-Way vs 4/2-Way Hydraulic Solenoid Valves

Hydraulic solenoid valves are commonly available in 4/3-way and 4/2-way configurations, depending on the control requirements:

4/3-Way Valve

- Has four ports and three spool positions.

- Ideal for systems requiring a neutral or “center” state.

- Can hold, float, or relieve pressure when centered.

- Suitable for complex, multi-directional flow applications.

4/2-Way Valve

- Features four ports and two positions.

- Switches fluid flow between two actuator states – extend and retract.

- Perfect for simple, binary operations where intermediate states aren’t required.

Selection Criteria - Choose the Right Solenoid Valve

When selecting a hydraulic solenoid valve, consider the following factors:

Parameter | Description |

Function | Choose between normally open, normally closed, or detent type based on system requirements. |

Pressure Rating | Ensure compatibility with system pressure (up to 350 bar / 5075 psi). |

Flow Rate | Select a valve rated for your hydraulic system’s capacity (typically 60-80 L/min). |

Port Size | Match to standard sizes such as NG6 (D03). |

Manual Override | Opt for manual override for maintenance or safety-critical operations. |

Types of Hydraulic Solenoid Valves

Hydraulic solenoid valves can be classified based on function and control characteristics:

- Directional Control Valves: Direct fluid flow paths within a hydraulic circuit. explore our directional control valve for more details.

- Pressure Control Valves: Maintain system pressure within safe operating limits.

- Flow Control Valves: Regulate the volume of hydraulic fluid passing through.

- Proportional Valves: Provide variable, precise control for complex automation needs.

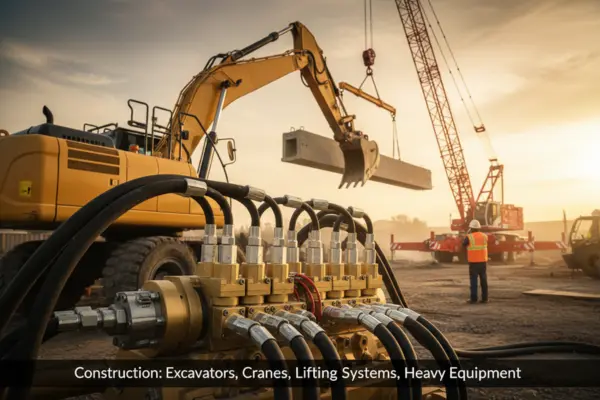

Applications Across Industries

Hydraulic solenoid valves are used extensively in industries where precision, power, and reliability are essential:

Hydrofit Engineers delivers custom-built solenoid valve solutions engineered to match your specific industry requirements.

FAQs

What is the main function of a hydraulic solenoid valve?

It regulates the flow and direction of hydraulic fluid using electrical control, enabling automated operation in hydraulic systems.

What’s the difference between 4/3-way and 4/2-way valves?

A 4/3-way valve includes a neutral middle position for pressure relief or hold functions, while a 4/2-way valve simply switches between two active positions.

How do I select the right valve for my system?

Consider flow rate, pressure rating, port size, default position, and whether manual override is needed for your application.

Can solenoid valves operate under high pressure?

Yes, high-quality hydraulic solenoid valves, such as those from Hydrofit Engineers, can operate efficiently up to 350 bar (5075 psi).