Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

PNEUMATICS

Pneumatics is a branch of engineering that deals with the study, design, and application of systems that use compressed air or gas to transmit and control mechanical energy. In pneumatic systems, compressed air serves as the medium for transmitting power and performing work, powering various types of machinery, equipment, and tools.

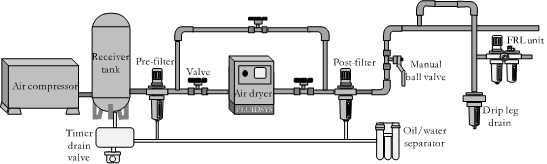

Pneumatic systems operate based on the principles of fluid dynamics, utilizing the properties of compressed air to generate mechanical motion. Compressed air is produced by compressors, which draw in ambient air and increase its pressure, reducing its volume. This compressed air is then stored in tanks or reservoirs and distributed through piping or tubing to pneumatic components and devices.

Pneumatic systems typically consist of several key components, including compressors, storage tanks, piping or tubing, valves, actuators, and control devices. Compressors generate compressed air, while storage tanks store the compressed air for use as needed. Valves control the flow of compressed air, and actuators convert the energy stored in compressed air into mechanical motion.

Pneumatic systems find widespread use in various industries and applications due to their efficiency, reliability, versatility, and safety. They are used in manufacturing and production processes, construction and building applications, transportation and logistics, healthcare and medical devices, agriculture and farming, entertainment and recreation, and many other areas.

Overall, pneumatics plays a vital role in modern engineering and technology, providing a cost-effective and efficient means of powering machinery, equipment, and tools in a wide range of industrial and daily life applications.

Components of Pneumatic Systems

Compressor

The compressor is the heart of a pneumatic system. It draws in ambient air and compresses it to a higher pressure, reducing its volume in the process. Compressors can be of various types, including reciprocating, rotary screw, and centrifugal, each with its own method of compressing air

Storage Tank

The compressed air generated by the compressor is stored in a tank or reservoir. This tank acts as a buffer, ensuring a steady supply of compressed air even during peak demand periods. It also helps dampen pressure fluctuations and serves as a source of compressed air for pneumatic devices.

Piping and Tubing

Piping or tubing is used to distribute the compressed air from the storage tank to various pneumatic components and devices throughout the system. It provides a pathway for the airflow and connects the different parts of the pneumatic system

Valves

Valves control the flow of compressed air within the pneumatic system. Directional control valves determine the direction of airflow, allowing for the activation and deactivation of pneumatic actuators and devices. Pressure and flow control valves regulate the pressure and rate of airflow to pneumatic components

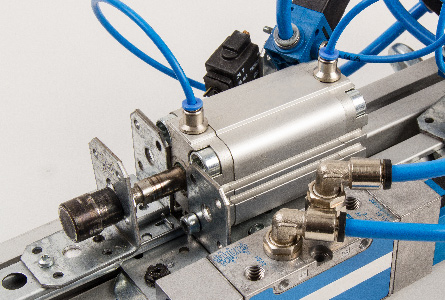

Actuators

Actuators are devices that convert the energy stored in compressed air into mechanical motion. They include pneumatic cylinders, rotary actuators, and air motors, which produce linear or rotary motion to perform work in pneumatic systems

How Pneumatic Systems Work

Compression of Air

The process begins with the compression of ambient air by the compressor. The compressor draws in air and increases its pressure, resulting in compressed air

Storage

The compressed air is then stored in a tank or reservoir, where it is held at a high pressure until needed. The storage tank ensures a steady supply of compressed air and provides a reservoir for pneumatic devices to draw from

Distribution of Compressed Air

Piping or tubing carries the compressed air from the storage tank to various pneumatic components and devices throughout the system. Valves control the flow of air, directing it to different parts of the system as needed

Conversion of Energy

Pneumatic actuators receive the compressed air and convert its energy into mechanical motion. Pneumatic cylinders extend or retract, pneumatic motors rotate, and pneumatic valves open or close in response to the airflow, performing the desired work

Control and Regulation

Control devices such as pressure regulators, flow control valves, and directional control valves regulate the pressure, rate, and direction of airflow within the pneumatic system. This allows for precise control over the operation of pneumatic devices and ensures optimal performance

In summary, pneumatic systems work by using compressed air to generate mechanical motion, with compressors, storage tanks, piping, valves, and actuators working together to power various industrial and mechanical applications

Benefits of Pneumatic Systems

Cost Effectiveness

Pneumatic systems are often more cost-effective than their hydraulic or electric counterparts. Compressed air is readily available and relatively inexpensive compared to other energy sources. Additionally, pneumatic components tend to be simpler, lighter, and more affordable, resulting in lower initial investment and operational costs

Versatility

Pneumatic systems can be used in a wide range of applications across different industries. From manufacturing and automotive to construction and agriculture, pneumatic tools and equipment are versatile solutions for powering various tasks such as drilling, cutting, lifting, and conveying

Safety

Pneumatic systems are inherently safer than some other power transmission methods. Unlike electrical systems, pneumatic systems do not pose the risk of electric shock or fire hazards in certain environments. Additionally, pneumatic tools are often designed with safety features such as dead-man switches to prevent accidental operation

Clean and Environmental Friendly

Compressed air is a clean and environmentally friendly energy source. Unlike hydraulic systems that use oil as a medium, pneumatic systems do not risk oil leaks or contamination, making them suitable for applications where cleanliness is critical, such as food processing or pharmaceutical manufacturing

Ease of Installation and Maintenance

Pneumatic systems are relatively easy to install, operate, and maintain. They require fewer components and less complex infrastructure compared to other power transmission systems, reducing installation time and costs. Routine maintenance tasks such as lubrication and filter replacement are straightforward, minimizing downtime and maximizing productivity

Fast and Responsive Operation

Pneumatic systems offer rapid response times and precise control over motion and force. Compressed air can be quickly distributed and regulated using valves and actuators, allowing for fast cycle times and high-speed operation in industrial processes

Adaptability to Harsh Environments

Pneumatic systems can operate effectively in harsh environments where exposure to extreme temperatures, moisture, or contaminants is common. Sealed pneumatic components and corrosion-resistant materials are available to withstand challenging conditions, making pneumatic systems suitable for use in outdoor or hazardous environments

Pneumatics plays a significant role in modern industries by offering cost-effective, versatile, and reliable solutions for powering a wide range of mechanical tasks. From manufacturing and automation to construction and transportation, pneumatic systems continue to be indispensable tools for enhancing productivity, efficiency, and safety across various sectors.

Products used in a pneumatic system

Compressors

Compressors are the heart of pneumatic systems, responsible for compressing ambient air to higher pressures. They come in various types, including reciprocating, rotary screw, and centrifugal compressors

Storage Tanks

Storage tanks or reservoirs store the compressed air generated by the compressor. They provide a buffer to ensure a steady supply of compressed air during peak demand periods

Pipes and Tubes

Piping and tubing distribute the compressed air from the storage tank to various pneumatic components and devices throughout the system. They provide a pathway for the airflow and connect different parts of the pneumatic system

Pneumatic Valves

- Directional Control Valves: These valves control the direction of airflow within the pneumatic system, allowing for the activation and deactivation of pneumatic actuators and devices.

- Pressure Control Valves: Pressure regulators regulate the pressure of the compressed air within the system, ensuring it remains within safe operating limits.

- Flow Control Valves: Flow control valves adjust the rate of airflow to pneumatic devices, providing precise control over their operation.

Actuators

- Pneumatic Cylinders: Pneumatic cylinders use compressed air to produce linear motion, extending or retracting a piston within a cylinder.

- Rotary Actuators: Rotary actuators use compressed air to produce rotary motion, rotating a shaft or spindle.

- Air Motors: Air motors utilize compressed air to drive a rotor or turbine, generating mechanical power

Filter, Regulators and Lubricators (FRL Units)

- Filters: Pneumatic filters remove contaminants such as dust, dirt, oil, and water vapor from the compressed air stream, ensuring clean and dry air.

- Regulators: Pressure regulators control the pressure of the compressed air within the system, maintaining a predetermined pressure level.

- Lubricators: Lubricators add a controlled amount of lubricating oil to the compressed air stream, reducing friction and wear on pneumatic components.

Pressure Gauges

Pressure gauges provide visual indication of the pressure levels within the pneumatic system, allowing operators to monitor and adjust as needed

Pneumatic One Touch Fittings

Pneumatic fittings and connectors are used to connect pneumatic components and accessories, providing a secure and leak-free connection

Pneumatic Silencers

Pneumatic silencers reduce noise levels produced by pneumatic components during operation, improving the working environment and reducing noise pollution

Pneumatic Manifolds

Pneumatic manifolds distribute compressed air to multiple pneumatic devices or components from a single source, simplifying system design and installation

These are some of the key pneumatic products and accessories required for a pneumatic system. Depending on the specific requirements of the application, additional components may be needed to meet performance, safety, and regulatory standards

Indispensibility of Pneumatics in Industry and Daily Life

- Manufacturing and Production: Pneumatic-systems are extensively used in manufacturing and production processes across industries such as automotive, aerospace, electronics, and consumer goods. They power assembly lines, robotic arms, material handling equipment, and precision tools, contributing to increased productivity, efficiency, and quality control.

- Construction and Building: Pneumatic tools are essential in construction and building applications for tasks such as drilling, nailing, cutting, and fastening. Pneumatic jackhammers, nail guns, concrete vibrators, and sanders make construction work faster, safer, and more cost-effective.

- Transportation and Logistics: Pneumatic-systems play a vital role in transportation and logistics, powering air brakes in commercial vehicles, pneumatic conveyors in material handling systems, and automated equipment in warehouses and distribution centers. They enable efficient movement of goods and materials, enhancing supply chain management and distribution processes.

- Healthcare and Medical: Pneumatic-systems are used in medical devices and equipment such as ventilators, dental chairs, surgical instruments, and blood pressure monitors. They provide precise control over airflow, pressure, and fluid movement in critical healthcare applications, contributing to improved patient care and treatment outcomes.

- Agriculture and Farming: Pneumatic-systems are utilized in agricultural machinery and equipment for tasks such as seed planting, crop spraying, and grain handling. Pneumatic actuators, valves, and controllers enable automated operation of agricultural equipment, optimizing crop yield, and farm productivity.

- Entertainment and Recreation: Pneumatic-systems are employed in entertainment and recreational activities, including amusement park rides, theatrical productions, and sporting events. They power special effects, stage automation, and equipment operation, enhancing the overall entertainment experience for audiences.

Benefits of Pneumatics in Industrial and Daily Activities

- Efficiency: Pneumatic systems offer high power-to-weight ratios and rapid response times, making them efficient for a wide range of industrial applications. They enable fast and precise control over mechanical motion, improving productivity and throughput in manufacturing and production processes.

- Versatility: Pneumatic-systems are versatile and adaptable, capable of powering various types of machinery, equipment, and tools. They can be easily integrated into existing systems or customized to meet specific application requirements, providing flexibility and scalability in industrial and daily life activities.

- Reliability: Pneumatic-systems are known for their reliability and durability, requiring minimal maintenance and downtime. They operate in harsh environments with temperature fluctuations, moisture, and contaminants, delivering consistent performance and longevity in industrial and daily life applications.

- Safety: Pneumatic-systems offer inherent safety features, such as overload protection, explosion-proof construction, and non-sparking operation. They eliminate the risks associated with electrical hazards, making them suitable for use in hazardous environments and critical applications where safety is paramount.

- Cost-Effectiveness: Pneumatic-systems are cost-effective solutions for powering machinery, equipment, and tools in industrial and daily life applications. Compressed air is readily available and relatively inexpensive compared to other energy sources, resulting in lower operating costs and higher return on investment-

Overall, pneumatics has become an indispensable part of today’s industry and daily life, offering numerous benefits such as efficiency, versatility, reliability, safety, and cost-effectiveness. Whether in manufacturing plants, construction sites, healthcare facilities, or entertainment venues, pneumatic systems play a vital role in powering a wide range of activities and applications, contributing to the advancement and improvement of society as a whole