Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

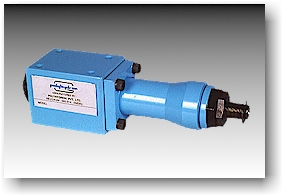

Hydraulic Pressure Control valves

Precision Pressure Management for Fluid Power Systems

Hydraulic pressure control valves is a core pressure stable elements in high-pressure hydraulic circuits. These valves control, hold and limit pressure to maintain system performance, operational safety and service life. High-Performance Hydraulic Pressure Control Valves Built for performance-oriented industrial applications, Hydrofit Engineers offer a complete line of precision-engineered hydraulic pressure control valves with long-lasting durability to withstand pressures.

What Are Hydraulic Pressure Control Valves?

In the fluid power industry, there are specific types of components called a hydraulic pressure control valves that are used to control system pressure, they help prevent overload and also stabilize circuit performance giving you optimal results thanks to smooth starting and stopping operations coupled with energy efficiency. Common functions are pressure control, pressure-limiting, pressure reduction, sequencing and unloading.

These valves are essential in hydraulic power packs, industrial machinery, mobile equipment, material handling units, forging presses, and process automation lines.

Key Features & Performance Characteristics

Hydrofit’s hydraulic pressure control valves deliver mission-critical operational benefits:

- Accurate pressure regulation under dynamic load conditions

- High repeatability for stable and consistent system performance

- Optimized flow paths for minimal pressure loss

- Robust construction suitable for severe-duty applications

- Multiple control configurations (direct acting, pilot operated)

- Enhanced safety through integrated pressure-limiting mechanisms

Types of Hydraulic Pressure Control Valves

Our products environment includes a variety of industrial-grade options to work in most any hydraulic system.

- Pressure Reducing Valves: These pressure reducing valves hold the pressure downstream in hydraulic system at a constant, pre-set level even if upstream pressures vary.

- Pressure Relief Valves: A hydraulic relief valve serves as both main safety device in an event of system over-pressure.

- Pressure Regulator Valves: Hydraulic regulator valves Regulator valves Automatically provide the required flow at a regulated pressure in any hydraulic system.

- Pressure Limiting Valves: Intended to establish upper pressure limits, these valves safeguard the system from overload, vibration, or sudden shock.

- Pressure Sequence Valves: The function can be used in hydraulic multi-stage for the performance of delayed manipulations, since the features are only activated after exceeding a defined pressure level.

Technical Specifications

Parameter | Specification Range |

Pressure Rating | 50 bar to 350 bar (725–5075 PSI) |

Valve Types Available | Pressure Relief, Pressure Reducing, Pressure Regulator, Pressure Limiting, Sequence Valve |

Flow Capacity | Up to 250 LPM (or model-specific) |

Construction Material | Cast Iron / Carbon Steel / Stainless Steel |

Mounting Style | Inline / Subplate / Manifold / Cartridge |

End Connections | BSP, NPT, SAE, Metric |

Operation | Direct Operated / Pilot Operated |

Medium | Mineral Oil / Synthetic Hydraulic Fluids |

Temperature Range | -20°C to +120°C |

Filtration Requirement | 10–25 Micron |

Adjustability | Manual Screw / Knob / Hex Key |

Sealing Options | NBR, FKM, PTFE |

Applications of Hydraulic Pressure Control Valves

These are important components and are used in many high-performance hydraulic systems. These are as follows:

Hydraulic Power Units & Manifolds

Agricutural and Mining Machinery

Metal Processing & Industrial Automation Lines

Material Handling & Lifting equipment

Molding Machines

They control pressure with high accuracy, to provide stability of systems, staff safety and long life of equipment.

Why Choose Hydrofit Engineers?

Hydrofit Engineers delivers value-driven hydraulic solutions backed by deep category expertise and robust manufacturing capabilities. Our pressure control valve portfolio is engineered for:

- Precision pressure management

- Long service life under severe-duty cycles

- Excellent repeatability and performance stability

- Industry-standard quality & compliance

- Reliable India-wide supply and technical support

We support both OEM integrations and end-user maintenance requirements with consistent performance across product lines. Feel free to contact us for best valve prices.