Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Hydraulic Filters

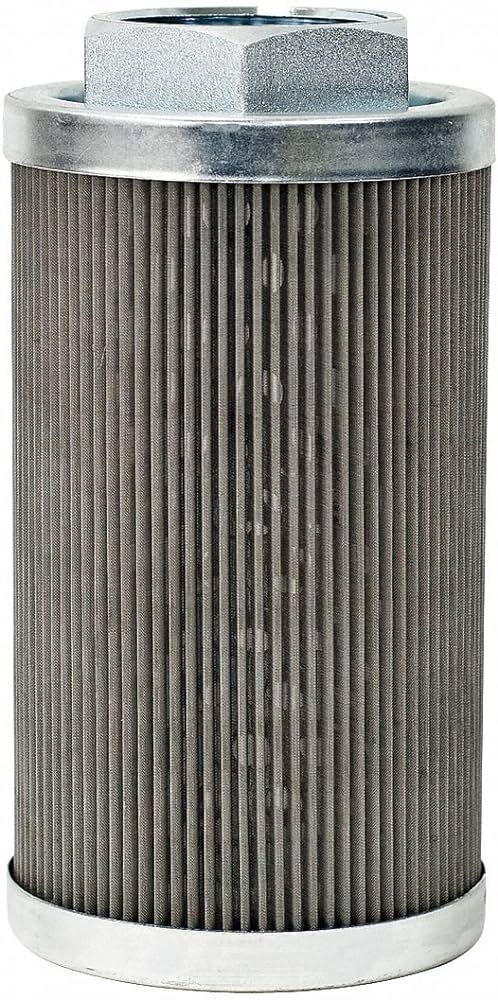

HYDRAULIC FILTERS

Hydraulic filters are vital for maintaining the cleanliness of hydraulic fluid, ensuring the efficient operation and longevity of hydraulic systems

What is Hydraulic Filtration ?

Hydraulic filtration is the process of removing contaminants from hydraulic fluid to ensure the efficient operation and longevity of hydraulic systems. Clean hydraulic fluid is critical for preventing wear and tear, reducing system failures, and maintaining optimal performance

Importance of Hydraulic Filtration

Protection of Components: Hydraulic systems consist of precision components such as pumps, valves, actuators, and cylinders. Contaminants can cause these components to wear prematurely, leading to failures and costly repairs.

System Efficiency: Clean hydraulic fluid ensures smooth operation, reducing friction and heat generation within the system. This enhances the overall efficiency and performance of the system.

Extended Equipment Life: By removing contaminants, hydraulic filters help prolong the life of hydraulic components and the system as a whole.

Reduced Downtime: Effective filtration reduces the likelihood of system failures and the need for unplanned maintenance, thereby minimizing downtime.

Cost Savings: Lower maintenance costs, reduced downtime, and extended equipment life contribute to significant cost savings over the long term.

Types of hydraulic filters, their working principles, functions, and place of use

Working Principle:

- Suction filters are positioned at the pump’s inlet and remove larger particles from the hydraulic fluid before it enters the pump.

- They typically consist of a wire mesh or coarse filter element that traps larger contaminants.

Function:

- Protects the hydraulic pump from large particles that could cause damage or wear.

- Prevents pump cavitation by ensuring a steady flow of fluid without significant restriction.

Places of Use:

- Installed in the hydraulic reservoir or inline before the hydraulic pump in various hydraulic systems.

Pressure Line Hydraulic Filters

Working Principle:

- Installed in the high-pressure line after the hydraulic pump, pressure filters capture contaminants generated during the operation.

- They have robust construction to withstand high pressure and often include fine filter media for effective filtration.

Function:

- Protects sensitive downstream components such as valves and actuators from contamination.

- Maintains the cleanliness of the fluid as it moves through the high-pressure side of the system.

Places of Use:

- Commonly used in industrial hydraulic systems, mobile machinery, and any application with high-pressure hydraulic circuits.

Working Principle:

- Positioned in the return line, these filters clean the hydraulic fluid before it returns to the reservoir.

- They typically feature fine filtration media and a bypass valve to ensure continuous fluid flow even if the filter becomes clogged.

Function:

- Captures contaminants that have entered or been generated within the system during operation.

- Ensures that only clean fluid returns to the reservoir, preventing reservoir contamination.

Places of Use:

- Found in various hydraulic systems, including industrial machinery, mobile equipment, and hydraulic presses.

Offline Kidney Loop Hydraulic Filters

Working Principle:

- These filters operate in a separate circuit from the main hydraulic system, continuously filtering a portion of the fluid.

- They have their own pump and filter housing, allowing them to operate independently of the main system.

Function:

- Provides additional fluid cleaning, reducing overall contamination levels.

- Extends the life of the hydraulic fluid and components by removing contaminants continuously.

Places of Use:

- Used in critical hydraulic systems where high fluid cleanliness is essential, such as in industrial machinery, hydraulic test stands, and power generation equipment.

Breather Hydraulic Filters

Working Principle:

- Mounted on the hydraulic reservoir, breather filters allow air to enter and exit the reservoir while filtering out airborne contaminants.

- They usually contain porous materials or mesh screens that trap dust and dirt particles.

Function:

- Prevents airborne contaminants from entering the hydraulic fluid through the reservoir.

- Maintains the cleanliness of the fluid by ensuring only clean air enters the system.

Places of Use:

- Installed on hydraulic reservoirs in various hydraulic systems, including mobile and industrial applications.

Dessicant Breathers - Hydraulic Filters

Working Principle:

- Similar to breather filters, but with the addition of desiccant materials that absorb moisture from the air.

- The desiccant changes color as it becomes saturated with moisture, indicating when it needs replacement.

Function:

- Prevents both airborne contaminants and moisture from entering the hydraulic system.

- Helps maintain fluid cleanliness and prevent corrosion by keeping the hydraulic fluid dry.

Places of Use:

- Used in hydraulic systems that operate in humid environments or where moisture control is critical, such as in offshore equipment and certain industrial applications.

In-tank Hydraulic Filters

Working Principle:

- These filters are integrated into the hydraulic reservoir and filter the fluid as it exits or returns to the tank.

- They typically have fine filter elements to capture small contaminants.

Function:

- Provides filtration within the reservoir, ensuring clean fluid circulation.

- Protects the entire hydraulic system by maintaining overall fluid cleanliness.

Places of Use:

- Commonly used in hydraulic power units, industrial machinery, and mobile hydraulic systems.

- Suction Filters: Protect pumps, used at pump inlets.

- Pressure Filters: Protect sensitive components, used after pumps in high-pressure lines.

- Return Line Filters: Clean returning fluid, used in return lines to reservoirs.

- Off-Line/Kidney Loop Filters: Provide continuous filtration, used in critical systems.

- Breather Filters: Prevent airborne contaminants, used on reservoirs.

- Desiccant Breathers: Prevent contaminants and moisture, used in humid environments.

- In-Tank Filters: Provide in-reservoir filtration, used in power units and machinery.

These filters ensure the hydraulic system’s efficiency, longevity, and reliability by maintaining fluid cleanliness and preventing contamination-related issues.