Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Hydraulic Hose with fittings (Hydraulic Hose assemblies)

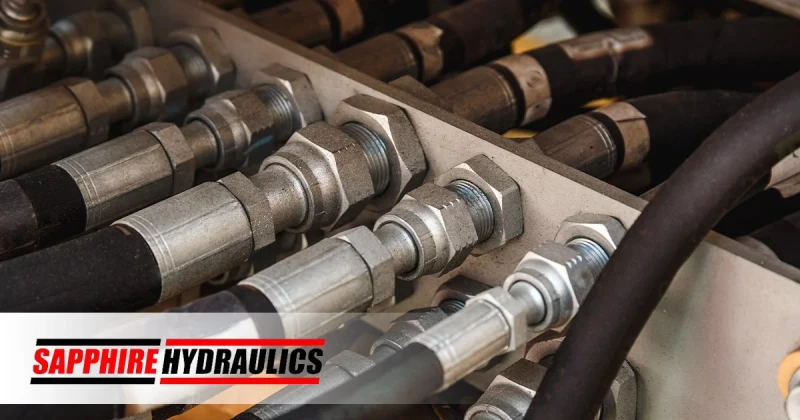

Hydraulic hose with fittings or hose assemblies are crucial components in hydraulic systems, used to convey hydraulic fluid between different parts of the system

Key components of Hydraulic Hose with fittings

The hydraulic hose with fittings or hydraulic hose assemblies comprise of 3 basic key elements :

- Hose: Typically made from synthetic rubber, thermoplastic, or reinforced with steel wire, the hose must be flexible and durable to withstand high pressure.

- Fittings: These are metal components attached to both ends of the hose, enabling connections to various parts of the hydraulic system. Fittings are often crimped onto the hose to ensure a secure and leak-free connection.

- Protective Cover: Some hoses have an additional outer layer to protect against environmental damage, abrasion, and chemicals.

Functions of Hydraulic hose with fittings

Hydraulic hose with fittings or hose assemblies are used to transfer hydraulic fluid – generally oil – from one part of the system to another allowing for the transmission of force from the power pack to the application where the work needs to be done. The hoses should handle high pressures ensuring that the hydraulic system operated efficiently and safely. The main advantage in using hydraulic hoses is that they offer flexibility, they allow for movement between different components of the hydraulic system, accommodating shifts and adjustments of the machinery or equipment during operation. The proper assembly of the fittings ensures there is no leakage in the hoses and fluid loss is prevented and system integrity is maintained

Process of Hose assembly

- Cutting the Hose: The hose is cut to the required length.

- Attaching Fittings: Fittings are placed on the hose ends and crimped or swaged to secure them.

- Testing: The assembly is pressure-tested to ensure it meets required standards and does not leak.

Hydraulic hose assemblies are essential for the proper functioning of hydraulic systems, ensuring fluid is transferred efficiently and safely under high pressure

Types of End fittings for Hydraulic hose assembly

Hydraulic hose assemblies come with various types of end connections to suit different applications and ensure secure, leak-free connections. The common types of end connections used in hydraulic hose with fittiings or assemblies are :

- JIC (Joint Industry Council) Fittings

- Description: Features a 37-degree flare seating surface.

- Common Uses: Used in a wide range of applications including automotive, industrial, and agricultural machinery.

- Advantages: Provides a reliable, high-pressure seal.

- NPT (National Pipe Tapered) Fittings

- Description: Tapered threads that seal when torqued.

- Common Uses: Often used in plumbing and low-pressure hydraulic systems.

- Advantages: Simple and cost-effective.

- ORFS (O-Ring Face Seal) Fittings

- Description: Flat face with an O-ring in the face to provide a leak-tight seal.

- Common Uses: High-pressure applications in industrial and mobile hydraulics.

- Advantages: Excellent sealing capability, especially for high-pressure systems.

- BSP (British Standard Pipe) Fittings

- Description: Comes in two types: BSPP (parallel) and BSPT (tapered).

- Common Uses: Widely used in Europe and the UK.

- Advantages: Reliable and versatile with good sealing properties.

- DIN (Deutsches Institut für Normung) Fittings

- Description: European standard fittings, including metric threads and a 24-degree cone.

- Common Uses: Common in European hydraulic systems.

- Advantages: High-pressure capability and compatibility with European equipment.

- SAE (Society of Automotive Engineers) Fittings

- Description: Includes various standards such as SAE J514 for hydraulic tube fittings.

- Common Uses: Automotive and industrial hydraulic systems.

- Advantages: Widely recognized and used, ensuring compatibility.

- Metric Fittings

- Description: Uses metric threads and dimensions.

- Common Uses: European and Asian machinery and equipment.

- Advantages: Compatibility with metric-threaded components.

- Flange Fittings

- Description: Consists of two halves with an O-ring in between, bolted together.

- Common Uses: High-pressure applications in industrial and mobile hydraulics.

- Advantages: Provides a strong, leak-free connection even in high-vibration environments.

- Camlock Fittings

- Description: Uses a cam and groove mechanism for quick connect/disconnect.

- Common Uses: Low to medium pressure applications where quick connect/disconnect is needed.

- Advantages: Easy and fast to connect and disconnect.

- Flat-Face Fittings

- Description: Features a flat face with an O-ring for sealing.

- Common Uses: High-pressure hydraulic systems, particularly in mobile and industrial applications.

- Advantages: Reduces the risk of leakage and contamination.