Contact : +91-79045 61980 | Email: hydrofitengineers@gmail.com

Working Principle of Tandem Gear Pumps

In this post we will understand the working principle of tandem gear pump, its advantages and applications as well. The positive displacement which drives the action of a tandem gear pump is that of capturing the fluid in varying volumes and then releasing (displacing) those trapped quantities into the discharge line.

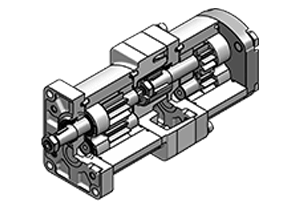

A tandem gear pump is distinguished by the fact that two or more gear pump sections are arranged in a housing, and driven by a common input shaft as opposed to only one gear section for the standard (single) gear pump. Hydrofit Engineers is the leading supplier of hydraulic gear pump in chennai.

Components of a Tandem Pump

- Gears: The tandem gear pump come with two sections and both have the pair of gears – a driving external gear and a driven internal gear. These gears are engaged in pumping.

- Housing: The gears are enclosed in a precision-machined housing to ensure that the high tolerances of these gears and bearings do not fit outside their design specifications, which could lead to an inefficient gear set.

- Shaft: A single input shaft drives the gears of each section within the tandem gear pump, ensuring synchronized operation of all sections for TGP without tramp.

Advantages of Tandem Pumps

Tandem-pumps are very versatile and able to supply fluid to several circuits with different performance requirements. This is perfect for advanced hydraulic systems that require different parts to be supplied with a specific pressure and flow rate. find the best price of tandem gear pump.

Space Saving: Tandem pumps combine two or more gear pump sections into a single unit, eliminating the need for additional independent pump packages and therefore requiring less space in hydraulic systems.

Economic: It may save costs for using a tandem-pump instead of two individual pumps. It also simplifies the hydraulic system and so reduces maintenance cost.

Durable and Trustworthy: Gear pumps are recognized for their reliability, and tandem-pumps are no different. They are able to work under high pressures and wear out less easily than other types of pump.

Modularity: These pumps can be manufactured based on process requirement (gear sizes, materials and other configuration), suited for various industries.

Working Principle of a Tandem Gear Pump

Rotation of the Input Shaft: Everything starts with the input shaft, generally attached to a motor or an engine. The shaft when it turns cause the gears of each pump section turning.

Fluid Intake: The gears rotate and as a result, there forms at the pump inlet a low-pressure zone (vacuum). It is this suction which causes the liquid in the reserve to be drawn into the pump case.

The fluid is introduced into interstices and shoes between teeth of the gears and housing walls.

Trapping and Transporting Fluid: As the gears turn, they move trapped fluid around the outer periphery of the gear housing.

The tight clearances between the gear teeth and housing prevent most back flow of liquid from discharge side to suction side.

Fluid Discharge: Once the gears get to the discharge side and the gear teeth un-mesh, fluid is pushed out of these pockets into the discharge line.

The released fluid moves on to the hydraulic system where it does work (moving a cylinder, driving a motor).

Independent Operation of Sections: Each section of a tandem gear pump can work separately and deliver fluid at varying flow rates or pressures.

In this way, a quantity of fluid under pressure is injected on the one hand in several hydraulic circuits by means of a single group and each circuit obtains from said pump only the suitable pressure and flow rate. know more about Tandem Pump Construction and Design.

Applications of Tandem Pumps

Twin pumps are applied in multiple industries where there is a demand for hydraulic power. Some common applications include:

Agriculture

In farming equipment time hitch, directional, or lift force for steering, lifting and driving downstream equipment are provided on tandem hydraulic gear pumps.

Engineering Machinery

Dual pumps are frequently employed in construction machinery, such as excavators, loader, crane onload and so on When handling hydraulic circuits requiring simultaneous input/output with different pressures and flows.

Automobile Industry

Tandem pumps are in addition used in the automobile industry, where they are used for power steering among other hydraulic applications with multiple fluid supplies.

Marine

Tandem pump finds application in marine vessels in hydraulic steering systems, stabilizers and control of different shipboard machineries from a single pump unit.

Industrial Equipment

In industrial machinery and manufacturing equipment, tandem pumps provide hydraulic power to various parts of the machine, including clamping systems, conveyors or brute cutting tools.

No matter what the type of hydraulic fitting is used, mobile or stationary, goal remains the same to achieve efficient service and extend fitting life by eliminating system downtime.

Finally, the concept for operation of a tandem gear pump is simple. Multiple gear pump sections are operated in unison within one housing. Each compartment sucks, catches and sends out liquid in the hydraulic liquid continuously can be delivered to a number of circuits having different pressure and flow speed values, all using only one input shaft.

This is what makes tandem drive gear pumps very efficient and flexible for the most challenging of hydraulic applications.